A-8

KING COBRA

®

500 - 56041964

5/10

INSTRUCTIONS FOR USE

A - ENGLISH

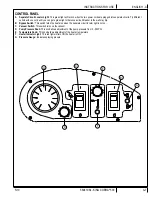

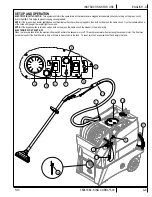

SET-UP AND OPERATION

CAUTION!

Use care when handling hazardous chemicals.

Never leave the machine running when you are not actively using it.

To avoid vacuum motor damage, always make sure the

fl

oat

fi

lter is clean and that it can travel freely before you operate the machine. Always use a defoamer

any time foam is present.

DANGER!

Do NOT use solvents, or any chemicals that may be

fl

ammable, explosive or combustible.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse or detergent (6 to 10 pH) in the King Cobra to prevent

premature wear of the pumps, seals, and other components. Damage caused by the use of improper or strong chemicals is not covered by warranty. Powdered

chemicals are not recommended.

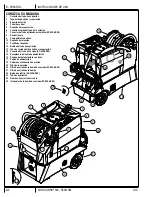

1

Before each use, inspect the machine, hoses, and cleaning tools for cleanliness and completeness. Make sure the hoses are in good condition and the

spray nozzle(s) is tight. Be sure the Pre-Filter Bag

(22 / KC-500-ADAF only)

and the Dump Pump Inlet Filter

(21)

are installed and are clean.

2

KC-500-ADAF:

When not using the auto-dump feature, just make sure the brass cap is screwed tightly on the Dump Hose Connection

(16)

on the dump

pump on the rear of the machine. If you choose to use the auto-dump, connect the dump hose to the Dump Hose Connection

(16)

on the back of the dump

pump, and place the open end of the hose in a drain. Make sure the Recovery Tank Drain Hose

(15)

is closed, and the Recovery Tank Lid

(2)

is closed tight.

REFER TO THE AUTO-FILL AND AUTO-DUMP INSTRUCTIONS ON THE FOLLOWING PAGES.

3

KC-500-ADAF:

If you choose to use the auto-

fi

ll feature, connect the

fi

ll hose to the Auto-Fill Hose Connector

(7)

. Turn on the water source, and allow the

tank to

fi

ll with water. When using the auto-

fi

ll system, the auto-

fi

ll

fl

oat will automatically turn on and turn off as the tank empties and then

fi

lls.

NOTE:

If you

are not going to use the auto-

fi

ll system, just

fi

ll the tank with water and cleaning chemical. Follow chemical directions regarding dilution and mixing. Do not

use harsh chemicals; they may damage seals in pumps and valves, and cause the pump to wear prematurely.

NOTE:

Using warm water in the tank may improve the ef

fi

ciency of the heat exchanger when cleaning with heat, but never use water with a temperature

exceeding 130 °F / 54 °C.

4

Pre-spray the area to be cleaned, with a pump-up sprayer, while the tank is

fi

lling. Follow chemical directions.

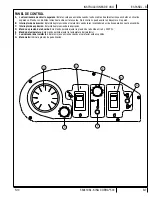

5

Plug in the power cords

(17)

.

Do not connect both cords to the same outlet. The green, ‘separate circuit’ locator light

(A)

on the switch plate should light

up. If the locator light does not come on, check the circuit breaker box in the wall, and/or try different outlets until it does turn on.

If you are certain the

cords are on separate circuits, turn the Bypass switch

(B)

on.

CAUTION:

using the Bypass switch

(B)

when the cords are on the same circuit may cause the breaker in the wall to trip.

NOTE:

the

receptacle

(15)

on the left (viewed from behind the machine) powers the heater.

The red light

(F)

will turn on only when the heat exchanger is actively heating.

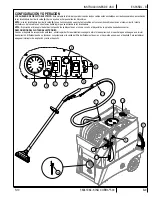

6

Press the lever on the Pressure Relief Valve

(18)

to make sure there is no back pressure in the system.

7

Connect the priming/siphon hose to the Solution Hose Quick Connect

(6)

, turn the pump ON by turning the Pump Pressure Knob

(D)

up to increase pump

speed and turn the Vacuum Switch

(C)

on. Place the open end of the priming hose into the Vacuum inlet hose barb

(1)

. Use your hand to block the open

area in the hose barb. This will allow the pump and the vacuum to work together to get the water moving. The air should prime out of the pump within 20 -

60 seconds. Watch the water

fl

ow into the recovery tank. When the water is clear (no air in it) and is

fl

owing strongly, turn both the pump and the vacuum

off, and remove the priming hose. NEVER remove the priming hose while the pump is still running.

8

Connect the Solution Hose

(19)

from the reel to the Solution Hose Quick Connect

(6)

and connect the Vacuum Hose

(23)

from the reel to the Vacuum Hose

Connection

(1)

. Connect both hoses to the cleaning tool.

9

Set the Temperature Knob

(E)

to the desired heat setting. Allow the heat exchanger two minutes to reach operating temperature. The red light

(F)

will go out

when the heater has reached operating temperature.

NOTE:

The red light will be on nearly all the time as you clean.

10 Turn the pump on by setting the Pump Pressure Knob

(D)

to the desired spraying pressure (0 - 500 PSI). Read the spraying pressure at the Pressure Gauge

(G)

while spraying.

NOTE:

when you let off the trigger on the wand, the pressure gauge reading will drop to 0 psi; however, the spraying pressure will

remain at the level to which you have set it. Turn the Vacuum Switch

(C)

ON.

NOTE:

the vacuum motor will start up slowly to prevent a large current surge.

KC-500-ADAF:

Turn on the dump pump

(25)

.

NOTE:

The dump pump will automatically turn on and turn off as the tank

fi

lls and then empties. It may take

several cycles to heat the lines and the cleaning tool.

11 If you are not using the auto-

fi

ll and auto-dump features, turn off both the pump

(D)

and vacuum

(C)

when the Holding Tank gets low,

fi

ll the Holding Tank,

and empty and clean the recovery tank.

12 Begin

cleaning.

13 Use defoamer in the recovery tank any time foaming occurs.

14 When

fi

nished with the job, remove any unused solution from the solution tank, and run a few gallons of clean water through the system. Drain the recovery

tank by placing the dump hose over a drain, or a bucket, and removing the cap. Disconnect the hoses from the cleaning tool, and reel them up onto the hose

spool.

NOTE:

To remove the reel, with hoses, from the machine, pull the vacuum hose loose from the hose barb on the front of the tank. Disconnect the solution hose

quick coupling. Push Vacuum hose into the center of the hose spool. Grasp the spool from either side, and lift it off the machine.

NOTE:

before servicing any

component in the base cabinet, the hoses and spool must be removed from the machine before the tanks can be lifted open.

5/12

Summary of Contents for King Cobra KC-500

Page 13: ......

Page 25: ......

Page 46: ...WATER FLOW DIAGRAM 1 2 3 4 5 9 6 8 11 7 10 D 10 KING COBRA 500 56041964 5 10 PARTS LIST...