8

SOLUS

®

500R - 56041970

6/07

INSTRUCTIONS FOR USE

A - ENGLISH

SET-UP AND OPERATION

CAUTION!

Use care when handling hazardous chemicals.

Never leave the machine running when you are not actively using it.

To avoid vacuum motor damage, always make sure the

fl

oat

fi

lter is clean and that it can travel freely before you operate the machine. Always

use a defoamer any time foam is present.

DANGER!

Do NOT use solvents, or any chemicals that may be

fl

ammable, explosive or combustible.

CLEANING SOLUTIONS:

Select a proper pre-spray for the surface to be cleaned, and apply the pre-spray. Use a neutral pH rinse or detergent (6 to 10 pH) in the Unit to

prevent premature wear of the pumps, seals, and other components. Damage caused by the use of improper or strong chemicals is not covered

by warranty. Powdered chemicals are not recommended.

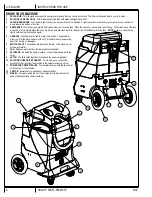

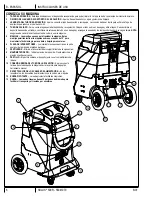

1.

Fill the holding tank

(2)

with clear water and pre-spray with the detergent of your choice (we recommend a CRI approved chemical). Mix well.

Although this machine is designed to supply instant hot water, the addition of warm water to the holding tank would increase heater ef

fi

ciency.

Never use water above 130º F/54º C in the solution tank.

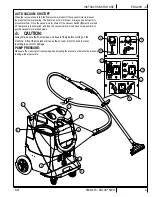

2.

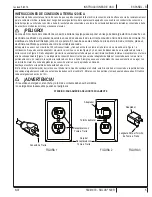

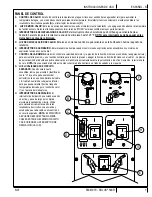

Turn off all the switches. Plug in cord #1. (This cord runs the pump and vacuum).

NOTE: TURN THE HEAT RECIRCULATION SWITCH

OFF BEFORE PRIMING THE PUMP.

3.

Attach the priming hose to the Solution Hose Quick Connect

(10)

and place the open end into the vacuum tank.

4.

Turn on the pump (turn pump pressure dial

(F)

all the way clockwise) and let it run until the pump is fully primed (approximately 30 seconds

to 1 minute). Once the pump is primed, turn off the pump and disconnect the priming hose. Attach the cleaning hose

(3 & 10)

and tool.

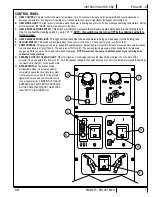

IF YOU WANT HEATED SOLUTION:

5.

Plug in the heater cord (identi

fi

ed by “H” on the back of the machine).

NOTE:

If the Separate Circuit Locator Light

(G)

does not illuminate

when the heater cord is plugged in, then both cords are on the same circuit. Try other outlets until the light comes on. See Bypass Switch

section (below) if you are unable to get a green light.

6.

Turn the Heat Control

(A)

clockwise to the desired temperature.

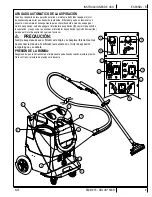

IF YOU WANT TO PRE-HEAT THE SOLUTION IN THE HOLDING TANK:

7.

Turn on both the pump

(F)

and heat recirculation switches

(C)

.

NOTE:

this switch will recirculate heated water back to the holding tank, until

it reaches 125 °F. At that point, the recirculation will automatically stop. If the temperature of the water in the tank drops below 125 °F, and if

the recirculation switch is still turned ON, the system will begin to recirculate the water again until it gets back up to 125 °F. You can choose

to let the solution in your holding tank reach 125° or you can choose to begin cleaning sooner than that.

NOTE

: the time that it will take for your solution to reach 125 °F will vary with the temperature of the solution that you put into the tank, the

ambient temperature, the amount of solution in your tank, etc.

8.

Turn on the pump

(F)

and spray through your tool a few times to

fi

ll the lines with solution. Begin cleaning.

9.

Re

fi

ll and empty the tanks as necessary.

10.

When

fi

nished with the job, vacuum all unused solution into the recovery tank, and dump the tank. Clean the tanks and

fi

lters. Clean the tool

and hoses. Store the machine in a heated location.

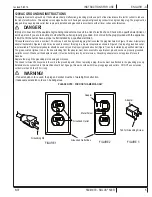

SEPARATE CIRCUIT LOCATOR

This unique, patented “smart system,” operated by a solid state circuit, will inform the operator when the two cords are plugged into separate lines

by illuminating the green, indicator light. This helps prevent tripping circuit breakers.

YOU MUST TURN THE HEAT RECIRCULATION SWITCH OFF BEFORE YOU CAN PRIME THE PUMP AND BEFORE YOU BEGIN

CLEANING, OTHERWISE YOUR PUMP PRESSURE WILL BE VERY LOW.

BYPASS SWITCH

The Bypass Switch

(H)

completely bypasses the separate circuit locator system. Use this feature when you cannot get the green Circuit Locator

(G)

to come on and you believe that the two cords are on separate circuits.

CAUTION:

If the bypass switch is on when the two cords are plugged into the same circuit, the breaker in the wall panel may trip.

Summary of Contents for Solus 500R

Page 32: ......