Part # 4517385 (02/20/08)

Page 10

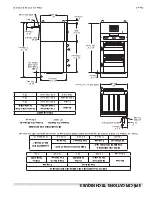

On a single broiler unit the grease drawer is located inside

the valve panel. On a double broiler the grease from the

upper broiler section drains into a container suspended

from the front of the unit. The grease from the lower broiler

section drains through the hopper into a grease drawer

located inside the valve panel.

Remove and clean the grid rack inserts and grease drip chute

daily. Pull the grid rack forward and lift the grease rack insert

out of the frame. Remove the grease drip chute by pulling it

forward out of the rack frame guides.

Instructions For Removal Of

Grid Rack & Grid Rack Frame

Remove the broiler grid racks as follows:

1. Bring the grid rack down to the lowest adjustment

position.

2. Pull the entire grid rack out of the broiler as far as

possible.

3. Remove grid rack grease drip chute (located below wire

rack) by grasping hold of the chute and pulling forward

out of the frame guides.

4. Remove wire racks by lifting the front of each wire rack

over the rack front plate.

5. Pull the empty grid rack frame assembly as far forward

as possible (until the stops hit the front of the carriage

assembly), lift up on the handle and pull the rack

frame forward so the stops clear the carriage assembly.

Continue pulling the rack frame forward until the rear

bearings reach the notches in the carriage tracks and lift

the rear of the rack up and out of the carriage; the entire

frame is now free from the unit.

6. Place the rack raising lever in the highest position for

safety purposes.

Before cleaning the hopper, replace the grease drawer

to receive any drippings and solid particles freed by the

cleaning. The additional internal grease diverter should be

removed from the top section and cleaned at this time. The

diverter is removed by raising the rack assembly and lifting

up the front of the diverter. After disengaging the screws at

the front of the unit, pull the diverter forward and remove

from the unit.

Carriage mechanisms should be kept clean, particularly

around the roller bearings. If the roller bearings have been

washed clean or appear to be dry, they should be lubricated

using salt-free vegetable oil or a non-toxic high temperature

bearing lubricant.

Infra-Red Burners must be cleaned periodically by

a service professional.

CARE & CLEANING continued