INTRODUCTION & SPECIFICATIONS

Surface Prep

Division

P: 877-817- 6687 F: 813-621-7125

Visit us at www.ussaws.com

sales@ussaws.com

Read this entire operations and maintenance manual before using your new

tool. Pay close attention to the Rules for safer operation,

Dangers, Warnings and Cautions.

The purpose of safety symbols and explanations are to attract your atten-

tion to possible hazards and how to avoid them. The safety symbols and

explanations do not by themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper accident prevention

measures.

Table of Contents & Introduction ..................................................... 2

Symbols & Decals ................................................................... 3

Safety Instruction ................................................................... 4 - 5

Pre-Operation Checklist ..............................................................6 - 8

Operation & Parts ................................................................... 9 - 15

Related Products ..................................................................... 16

Warranty & Service ............................................................. 17 - 18

1.0

INSTRUCTIONS FOR USE OF MANUAL SECTIONS

Section Page

2.0 SPECIFICATIONS

Foreword/Introduction

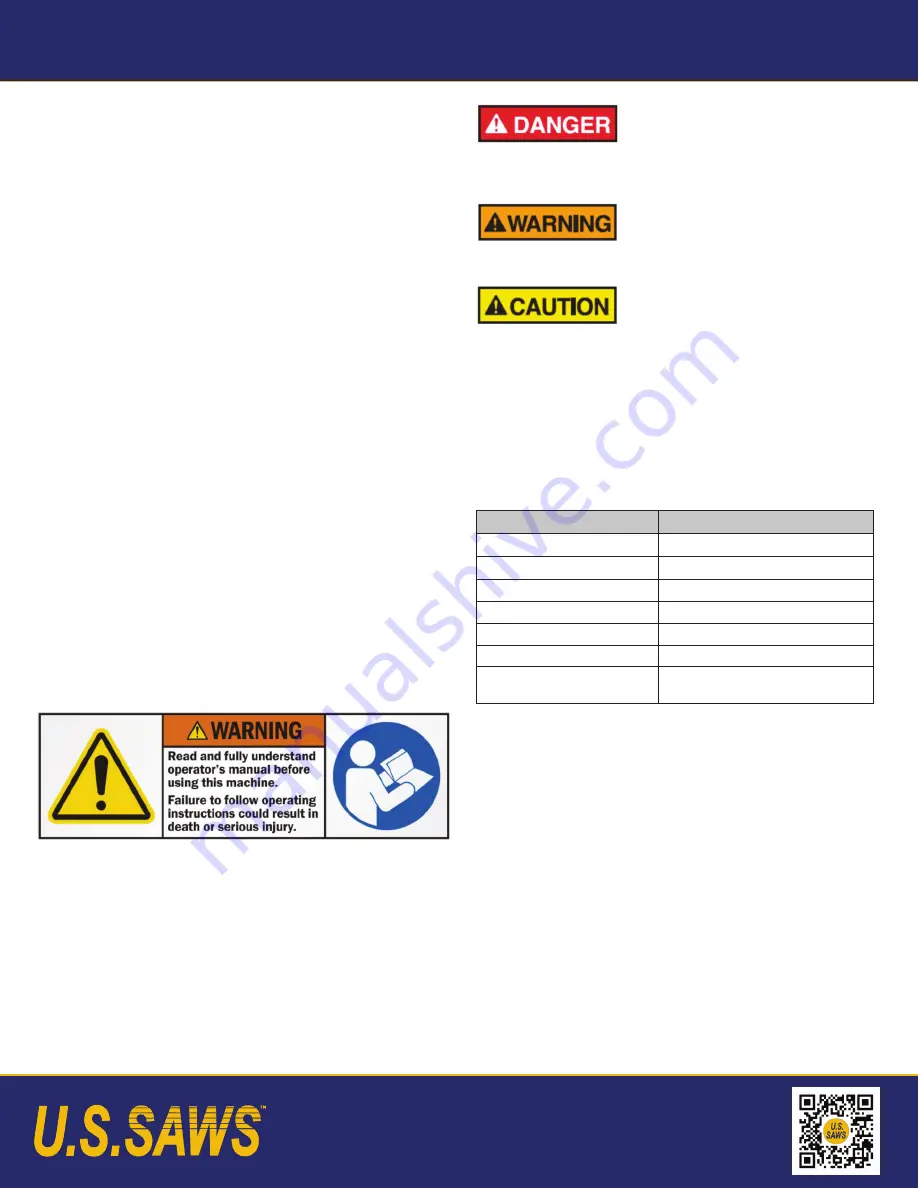

DANGER:

Indicates an imminently hazardous situation that if not

avoided, will result in death or serious injury. This signal word is lim-

ited to the most extreme situations.

WARNING:

Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation that, if not

avoided may result in minor or moderate injury. It may also be used to

alert against unsafe practices that may cause property damage.

2

The owner’s manual is intended to point out some of the basic safety situa-

tions that maybe encountered during the normal operation & maintenance

of the U.S.SAWS MARK III Machine & to instruct you in safety practices for

dealing with these conditions. Keep all manuals provided with your

machine in a safe place at all times.

The information and specifications included in this publication were

in effect at the time of approval for printing. U.S.SAWS reserves the right,

however, to discontinue or change specifications or design at any time with

-

out notice and without incurring any obligation.

The U.S.SAWS Mark-III is a high preformance, high precision saw designed

to clean out control joints, remove old joint filler, and make straight accurate

cuts in concrete up to 2” deep.

Typical applications for the U.S.SAWS MARK III are to clean out control

joints, remove old joint filler, and make straight accurate cuts in concrete

up to 2” deep. A specially designed blade guard allows the operator to

see the blade yet still covers 98% of it for excellent dust control and a high

drgree of accuracy. Blade depth is fully adjustable and has a depth lock to

prevent over cutting. The concrete cleanout saw fully complies with ANSI

diamond blade speed regulations.

TO PREVENT SERIOUS INJURY DO NOT OPERATE SAW WITHOUTPROPER TRAINING AND.

UNDERSTANDING OF THE OWNERS MANUAL

WHEN OPERATING THIS MACHINE

ALWAYS WEAR SAFETY APPROVED

HEARING PROTECTION

EYE OR FACE PROTECTION

PROTECTIVE HELMET

PROTECTIVE GLASSES OR FULL FACE PROTECTION

WEAR HAND PROTECTION

WARNING: Improperly maintaining the JS including the Honda engine or failing to correct a problem before

operation could cause a malfunction resulting in a serious injury. Always perform a pre-operation inspection before

each operation and correct any problem. See Honda Engines Owner's Manual.

5.2

Check the condition of the Honda engine. See the section titled "Before operation - is your

engine ready to go?" in the Honda Engines Owner's Manual.

WARNING: Exhaust gas from gasoline engines contains dangerous carbon monoxide. Breathing it can cause

unconsciousness and even kill you. Always operate gasoline engine machines in a well-ventilated area. Do not

operate in areas where exhaust fumes could accumulate without wearing appropriate respiratory protection.

Consult your employer and OSHA regarding use of appropriate respirator for dangerous carbon monoxide

gases. See Figure 7.

EEnnggiinnee eexxhhaauusstt ccoonnttaaiinnss

ppooiissoonnoouuss ccaarrbboonn

m

moonnooxxiiddee ggaass.. Breathing

it could cause death.

Operate machine in well

ventilated area.

FFiigguurree 77 -- W

Waarrnniinngg llaabbeell -- eennggiinnee eexxhhaauusstt ccoonnttaaiinnss ccaarrbboonn m

moonnooxxiiddee ggaass

1111

Production rates vary but a good operator can easily clean out 10,000 linear

feet of new, unfilled joints in an 8-hour shift.

MADE IN USA 25 Year Warranty on Chassis

Model

MarkIII Dust Buggy

Part Number

SX13700

Grinder Make/ Model

Metabo W24-230

Output Power

15 Amp Electric

Max RPM

6,600

Power Requirments

115V, 60Hz

Max Cutting Depth

2”

Blade Diameter

7” or 8”

Dry Diamond