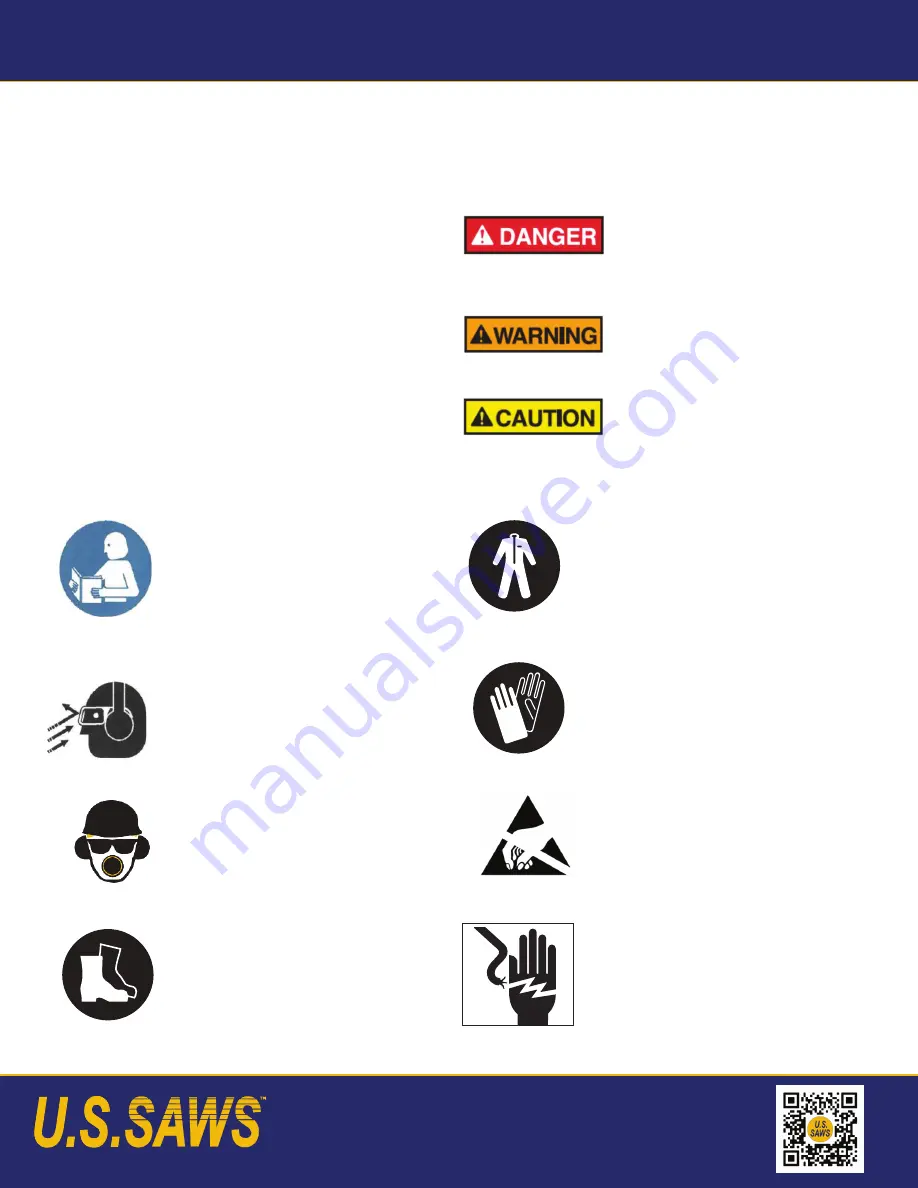

SYMBOLS & DECALS

WARNING

Read and understand

operator's manual before

using this machine.

Failure to follow operating

Instructions could result

in injury or damage to

equipment.

Use only diamond blades (steel

centered diamond cutting-off

wheels) with this machine. RPM

rating on blade must exceed

machine max rpm rating. The use

of any other blade could result in

death or serious injury.

5400 MAX. RPM

Avoid injury.

Do NOT operate with

guard removed.

Replace guard before

operating machine.

C1 hazard Communication Sywems. LLLLC

C

M

MO

O--7

74

46

6--0

02

24

41

1

To avoid injury:

Always inspect saw

blades before use.

Replace all cracked or damaged

blades.

Rotating blade

hazard.

Do NOT operate with

guard up.

Keep hands and feet

away.

Engine exhaust

contains poisonous

ccaarrbboonn m

moonnooxxiiddee ggaass..

Breathing it could cause

death.

Operate machine in well

ventilated area.

This product can expose you to chemicals, including NICKEL. When used, serviced, cleaned, or maintained equipment could generate particulates

that contain chemicals, including silica. These chemicals are known to the state of California to cause cancer and birth defects or other

reproductive harm. For more information, visit

www.P65Warnings.ca.gov

4.0

Rules for safer operation

WARNING

Read and understand

operator's manual before

using this machine.

Failure to follow operating

Instructions could result

in injury or damage to

equipment.

Use only diamond blades (steel

centered diamond cutting-off

wheels) with this machine. RPM

rating on blade must exceed

machine max rpm rating. The use

of any other blade could result in

death or serious injury.

5400 MAX. RPM

Avoid injury.

Do NOT operate with

guard removed.

Replace guard before

operating machine.

C1 hazard Communication Sywems. LLLLC

C

M

MO

O--7

74

46

6--0

02

24

41

1

To avoid injury:

Always inspect saw

blades before use.

Replace all cracked or damaged

blades.

Rotating blade

hazard.

Do NOT operate with

guard up.

Keep hands and feet

away.

Engine exhaust

contains poisonous

ccaarrbboonn m

moonnooxxiiddee ggaass..

Breathing it could cause

death.

Operate machine in well

ventilated area.

This product can expose you to chemicals, including NICKEL. When used, serviced, cleaned, or maintained equipment could generate particulates

that contain chemicals, including silica. These chemicals are known to the state of California to cause cancer and birth defects or other

reproductive harm. For more information, visit

www.P65Warnings.ca.gov

4.0

Rules for safer operation

3

Read and understand operator’s

manual before using this machine.

Failure to follow operating Instruc-

tions could result in injury or dam-

age to equipment.

Always wear protective glasses

or full face protection

Wear safety boots when

operating this machine

Wear appropriate clothing

Wear hand protection

Wear Head Protection, breath-

ing protection, and the use of

hearing protection is manda-

tory

TO PREVENT SERIOUS INJURY DO NOT OPERATE SAW WITHOUTPROPER TRAINING AND.

UNDERSTANDING OF THE OWNERS MANUAL

WHEN OPERATING THIS MACHINE

ALWAYS WEAR SAFETY APPROVED

HEARING PROTECTION

EYE OR FACE PROTECTION

PROTECTIVE HELMET

PROTECTIVE GLASSES OR FULL FACE PROTECTION

WEAR HAND PROTECTION

WARNING: Improperly maintaining the JS including the Honda engine or failing to correct a problem before

operation could cause a malfunction resulting in a serious injury. Always perform a pre-operation inspection before

each operation and correct any problem. See Honda Engines Owner's Manual.

5.2

Check the condition of the Honda engine. See the section titled "Before operation - is your

engine ready to go?" in the Honda Engines Owner's Manual.

WARNING: Exhaust gas from gasoline engines contains dangerous carbon monoxide. Breathing it can cause

unconsciousness and even kill you. Always operate gasoline engine machines in a well-ventilated area. Do not

operate in areas where exhaust fumes could accumulate without wearing appropriate respiratory protection.

Consult your employer and OSHA regarding use of appropriate respirator for dangerous carbon monoxide

gases. See Figure 7.

EEnnggiinnee eexxhhaauusstt ccoonnttaaiinnss

ppooiissoonnoouuss ccaarrbboonn

m

moonnooxxiiddee ggaass.. Breathing

it could cause death.

Operate machine in well

ventilated area.

FFiigguurree 77 -- W

Waarrnniinngg llaabbeell -- eennggiinnee eexxhhaauusstt ccoonnttaaiinnss ccaarrbboonn m

moonnooxxiiddee ggaass

1111

For Safe Operation

You must be qualified for safe operation of the U.S.SAWS

Valve Exerciser

machine. You must clearly understand the written instructions supplied

by U.S.SAWS, be trained - including actual operation - & know the safety

rules & regulations for the job site. It is a safety practice to point out & ex-

plain safety signs & practices to others & to make sure they understand

the importance of following these instructions.

Be Safe

Human error is the result of many factors: carelessness, fatigue, sensory

overload, preoccupation, unfamiliarity with the machine or attachments,

or drugs or alcohol, to name a few. You can avoid serious injury or death

caused by these & other unsafe work practices. Be safe and never as-

sume accidents cannot happen to you.

For your safety and the safety of others, act safely and encourage your

fellow workers to act safely as well.

Wear proper electrostatic

grounding equipment at all

times.

Wear proper electrostatic

grounding equipment at all

times.

3.0

SYMBOLS & DECALS

DANGER:

Indicates an imminently hazardous situation that if not avoided,

will result in death or serious injury. This signal word is limited to the most

extreme situations.

WARNING:

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation that, if not avoided

may result in minor or moderate injury. It may also be used to alert against

unsafe practices that may cause property damage.

Dangers, Warnings and Cautions.

The purpose of safety symbols and explanations are to attract your atten-

tion to possible hazards and how to avoid them. The safety symbols and

explanations do not by themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper accident prevention

measures.

Waterworks

Division

P: 866 987-7297 F: 813-621-7125

Visit us at www.ussaws.com

sales@ussaws.com