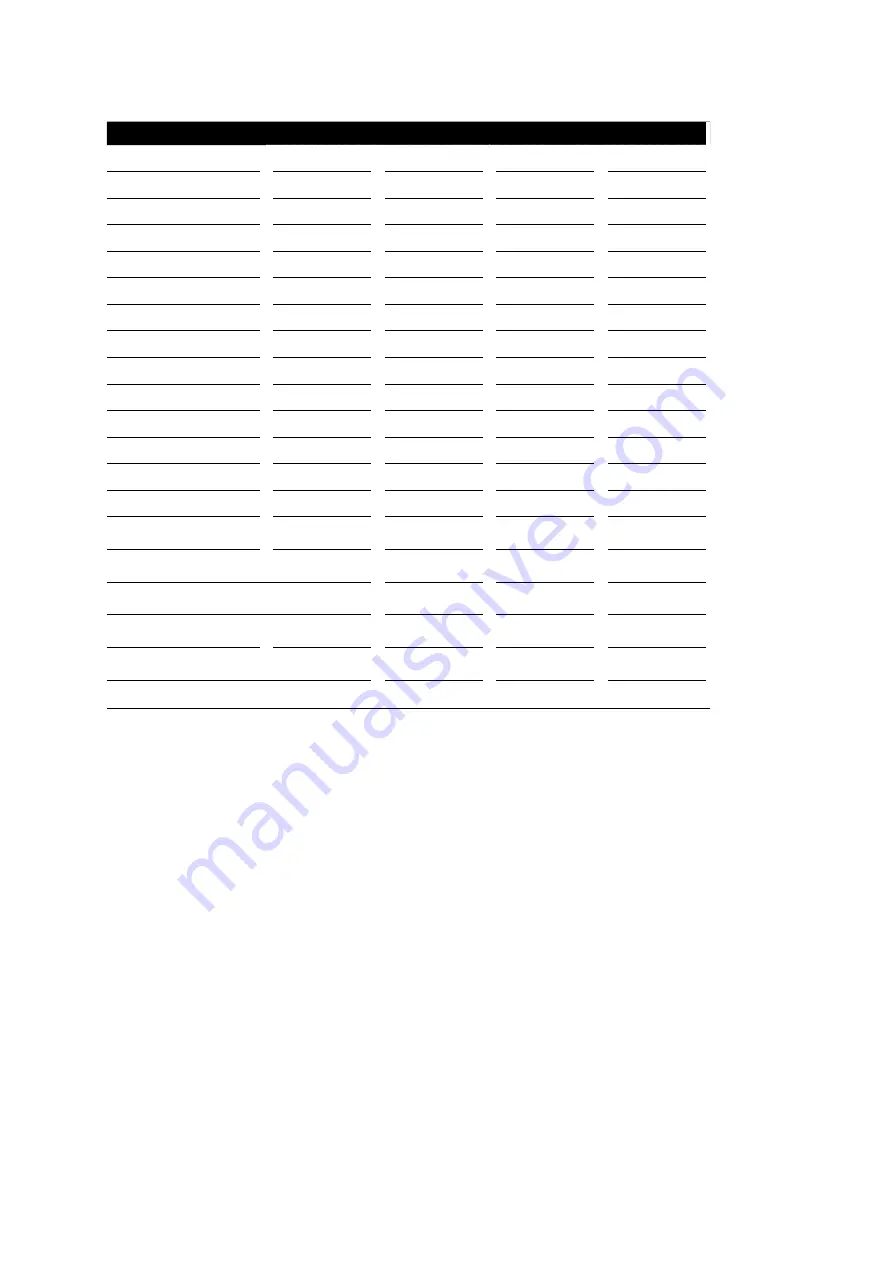

technical data u-turn BlacKlight 2

XS

S

M

L

Start weight

Startgewicht

55-80

65-90

80-105

95-120

Flat area

Fläche ausgelegt

22,6m²

24,8m²

27,2m²

29,2m²

Projected area

Fläche projiziert

19,641m²

21,553m²

23,639m²

25,377m²

Flat wingspan

Spannweite ausgelegt

11,26m

11,795m

12,353m

12,799m

Projected wingspan

Spannweite projiziert

9,127m

9,561m

10,013m

10,374m

Flat AR

Streckung ausgelegt

5,61

5,61

5,61

5,61

Projected AR

Streckung projiziert

4,241

4,241

4,241

4,241

Chord: center / wingtip

Flügeltiefe: Mitte / Stabilo

2,445 / 0,547 m

2,561 / 0,572 m

2,682 / 0,601 m

2,779 / 0,627 m

V-trim

V-Trimm

39 (+/-1) km/h

39 (+/-1) km/h

39 (+/-1) km/h

39 (+/-1) km/h

V-max

V-Max.

54 (+/-2) km/h

54 (+/-2) km/h

54 (+/-2) km/h

54 (+/-2) km/h

Bridle height

Abstand Tragegurt-Kappe

6,869m

7,195m

7,535m

7,807m

Nr. of cells

Zellenanzahl

59

59

59

59

Glider weight

Gewicht

4,3 kg

4,7 kg

5,3 kg

5,7 kg

Bridle length

Gesamt Leinenlänge

230,219m

238,925m

274,066m

306,446m

Line diameter

Leinenduchmesser

0,55 / 0,65 / 0,7 / 1,1

1,2 / 1,3 / 1,45 / 1,6 mm

0,55 / 0,65 / 0,7 / 1,1

1,2 / 1,3 / 1,45 / 1,6 mm

0,55 / 0,65 / 0,7 / 1,1

1,2 / 1,3 / 1,45 / 1,6 mm

0,55 / 0,65 / 0,7 / 1,1

1,2 / 1,3 / 1,45 / 1,6 mm

Speed system / trimmer

Fuß Beschleuniger / Trimmer

Yes / no

Ja / nein

Yes / no

Ja / nein

Yes / no

Ja / nein

Yes / no

Ja / nein

Certifi cation

Zulassung

en-B / LTf-B

en-B / LTf-B

en-B / LTf-B

en-B / LTf-B

Certifi ed standards and procedures

Angewandte Testverfahren

LTf 91/09 & en 926-

1:2006, 926-2:2013

LTf 91/09 & en 926-

1:2006, 926-2:2013

LTf 91/09 & en 926-

1:2006, 926-2:2013

LTf 91/09 & en 926-

1:2006, 926-2:2013

Folding lines used for certifi cation

Faltleinen für Testfl üge benutzt

no

nein

no

nein

no

nein

no

nein

Certifi cation No.

Zulassungsnummer

eAPr-GS-0537/16

eAPr-GS-0536/16

eAPr-GS-0535/16

eAPr-GS-0534 /16

errors and omissions expected. Subject to change without notice. reproduction in whole or in part without written permission of U-Turn GmbH is prohi-

bited.

Irrtümer, druckfehler und Änderungen bleiben vorbehalten. nachdruck auch auszugsweise, nur mit schriftlicher Genehmigung der U-Turn GmbH.

BLACKLIGHT 2

errors and omissions expected. Subject to change without notice. reproduction in whole or in part without written permission of U-Turn GmbH is prohibited.

Irrtümer, druckfehler und Änderungen bleiben vorbehalten. nachdruck auch auszugsweise, nur mit schriftlicher Genehmigung der U-Turn GmbH.

Summary of Contents for BLACKLIGHT 2

Page 2: ...REACH YOUR GOALS FASTER blacklight2 ...

Page 28: ...Leinenplan BLACKLIGHT 2 S ...

Page 29: ...MANUAL U TURN BLACKLIGHT 2 28 29 Leinenplan BLACKLIGHT 2 M ...

Page 30: ...Leinenplan BLACKLIGHT 2 L ...

Page 31: ...MANUAL U TURN BLACKLIGHT 2 30 31 ...