4

revised 09/09

Smog-Hog

SG Series Model

4.2 COLUMN OR WALL MOUNTING

units may be suspended from cantilevered supports

on walls or columns. SG-2 and SG-4S units may be

mounted against columns but should extend at least

24” from walls in keeping with good airflow practice.

SG-4T units require 36” clearance from walls and

columns for blower compartment access.

Prior to installation, refer to specifications in figures 1,

2 and 3. Note mounting and clearance requirements

and allow for proper plumbing and electrical access.

allow at least 36” for door swing and component access

on the door side of the unit. All SG models require 18”

clearance from overhead obstructions for access to

electrical junction boxes.

4. INSTALLATION

carefully remove the unit from the shipping con-

tainer, inspecting for shipping damage. for ease of

installation, open access door and remove unicells and

filters from the cabinet.

Units suspended from the ceiling require 1/2” threaded

rods installed in top corners of the units. See figure 2

for mounting hole locations for all models. additional

support should be used for auxiliary equipment or

ducting. the SG should not be used for support of

personnel or material.

reinstall the components which were removed ear lier

to facilitate mounting the unit.

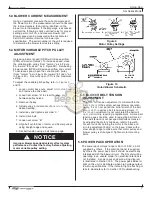

4.1 CEILING MOUNTING

SG units are designed for suspended mounting,

using 1/2” all-thread rod as shown in figure 4.

customer should take care to ensure that roof

trusses are adequate to support unit weight and

support members. in figure 4, angle iron cross

members are secured between roof trusses.

turnbuckles greatly simplify rod installation.

rod length should be kept to a minimum

36” preferred). all SG units have cross-broken

sheet metal sumps with drains centered under the

collection section.

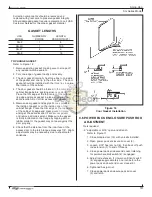

Model

Weight (lbs)

SG-2X

250

SG-2X-a

275

SG-2

400

SG-2-a

450

SG-4X

375

SG-4X-a

400

SG-4S

750

SG-4S-a

800

SG-4t

825

SG-4t-a

875

SG-6X

700

SG-6S

1,870

SG-6S-a

1,960

4.3 BOTTOM SUPPORTS

units may be supported from underneath, provided

care is taken to assure good drain connection and

leak-free sumps.

4.4 DRAINS

all SG units are supplied with 1 1/2” fPt drains. if dry

material is to be collected and in-place cleaning is not

supplied, then drain connection(s) should be plugged.

If in-place cleaning is supplied, or a liquid is collected

within the SG unit, refer to figure 5 for drain and drain

trap installation.

4.5 ELECTRICAL CONNECTIONS

all SG units are provided with terminal blocks in a

top-mounted electrical box for incoming power

connections. Units with blowers have box- mounted

step-down transformers to supply re quired 115 volts to

power packs. Units without blowers are equipped for

115 volt supply only (see figure 6).

Figure 4

Typical Ceiling Mount

Model SG-2

Figure 3

SG Unit Weights