7

revised 09/09

Smog-Hog

SG Series Model

5.3 BLOWER CURRENT MEASUREMENT

using an ammeter measure the current amperage of

the blower motor. The measurement should not exceed

the full load ampere (fLa) rating identified on the

blower motor nameplate. If the amperage is excessive,

perform the following: check overload relay for proper

setting per motor fLa, and measure blower rpm.

Blower speed can be measured with a tachometer.

call uaS customer Service for blower rpm

specification. The serial number of the unit is required

to determine the blower rpm factory setting.

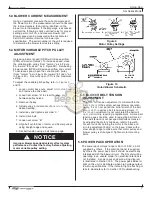

5.4 MOTOR VARIABLE PITCH PULLEY

ADjUSTMENT

increasing blower speed (rPM) will increase airflow

(cfM) and current (amps). to increase speed, close

the variable pitch pulley (from “normal,” as in figure

9a, toward “full closed,” as in figure 9B). Decreasing

blower speed (rPM) will decrease airflow and current.

to decrease speed, open the variable pitch pulley

(from “normal,” as in figure 9a, toward “full open,” as

in Figure 9C). Five turns open (T.O.) is the maximum

setting.

to adjust the variable pitch pulley, refer to figures 9

and 10.

1. Loosen motor base nuts, adjust motor slide base

and remove the drive belt.

2. Loosen set screw “a” to clear the drive key

between pulley halves.

3. remove the key.

4. adjust pulley in increments of one turn to the

desired setting.

5. install key and tighten set screw “a.”

6. install drive belt.

7. Loosen set screw “B.”

8. align belt centerlines of motor and blower pulleys

using straight edge and square.

9. Set belt tension using a belt tension gage.

Improper blower speeds adversely affect system

performance. Contact the factory before adjusting

motor variable pulley setting.

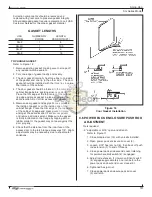

5.5 BLOWER BELT TENSION

ADjUSTMENT

the drive belt tension adjustment is critical within the

first 24 hours of the system exhaust blower operation.

During this 24 hour period the initial stretch of the belt

occurs which requires a belt tension adjustment. If

this tension adjustment is not completed the belt will

wear prematurely, requiring a replacement. A drive belt

tension gage should be used for adjusting belt tension.

if fan belt tension is not per specifications set tension

by adjusting the motor slide base, refer to figure10.

Loosen four bolts holding the motor to the base and

turn the adjustment bolt(s) on the base. check with a

steel straight edge to make sure that motor pulley and

blower pulley is still aligned. tighten motor mounting

bolts.

5.6 POWER PACK OPERATION

the power pack voltage range is 90 to 130 ac, 60 Hz,

supplied by others. if the electrical panel is supplied

by others the power pack circuit should be electrically

interlocked with the blower circuit. the SG unit will be

operating in an unsafe mode if an electrical interlock is

not installed. a power pack enclosure wiring diagram

is illustrated in Section 12.2. the power pack indicator

light on the unit is illuminated when high voltage output

is within specifications. if the indicator light is flashing or

fails to illuminate refer to Section 10 troubleshooting.

!

NOTICE

Figure 9

Motor Pulley Settings

Figure 10

Motor/Blower Schematic

9

9

9