8

revised 09/09

Smog-Hog

SG Series Model

5.7 POWER PACK ENCLOSURE PUSH ROD

AND GROUNDING BAR

each power pack enclosure has a captive, spring

loaded “push rod” extending into the module.

factory-set, the push rod serves the following purposes:

1. High voltage Dc power is automatically shut down

with the unicells removed from the module.

2. Whenever a module door or power pack enclosure

lid cover is opened, the limit switch is disengaged,

placing 115 Vac off line to the power pack.

3. opening either of the module door or the power

pack enclosure lid cover also releases a spring

loaded push-rod, placing the grounding bar in

contact with the cell door feed through insulator

acorn nut, removing residual cell voltage.

The opening of only the module door is such that

the grounding bar may not completely short out

the cell circuit as a precaution. Perform the

grounding procedure. Refer to Figures 14 and 15.

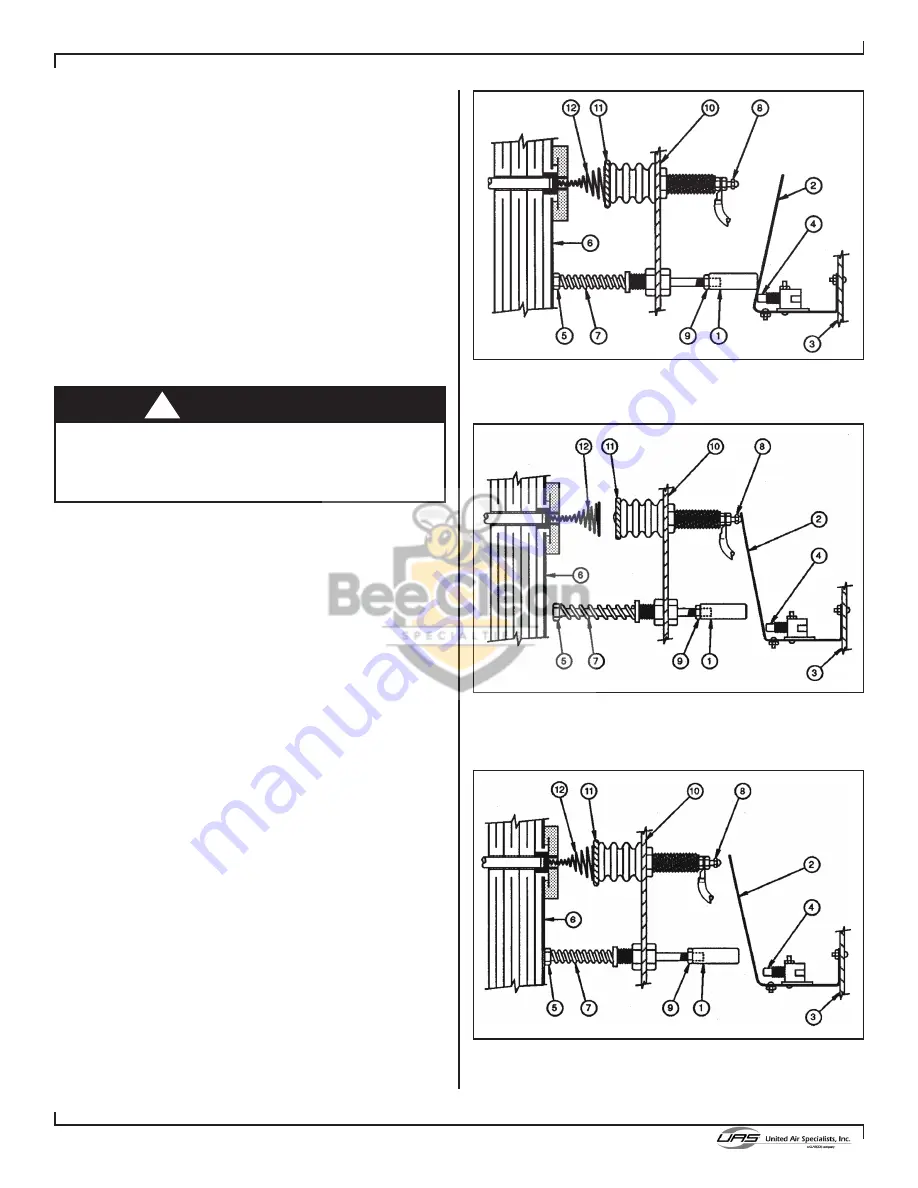

During normal operation, (refer to figures 11, 12 and

13) with unicells in place, the component door (10)

and the power pack door closed (3), the push rod (5)

is in contact with unicell endplate (6). Push rod

extension (1) is in contact with the ground bar (2) and

bends to contact the limit switch (4) refer to figure 11.

upon opening the component door (10), the push rod

(5) is released from the unicell endplate (6) and spring

(7) compression is relieved, breaking the contact of the

push rod extension (1) from the ground bar (2), placing

ac voltage off line to the power pack and causing the

grounding bar to contact the acorn nut (8), refer to

figure 12. When opening the power pack door (3),

the spring (7) remains compressed but the grounding

bar (2) is pulled from the push rod extension (1) as

the power pack door (3) is opened. ac voltage is

placed off line to the power pack by opening the limit

switch (4) which the unicells are grounded through

the acorn nut (8), but with the contact spring (12) fully

compressed, refer to figure 13.

5.8 IN-PLACE CLEANING (OPTIONAL)

the spray nozzles to the wash headers can become

clogged or otherwise obstructed due to debris within the

field piping. at initial start-up, water should be purged

before final pipe connection at the SG. the y strainer

to the detergent injector tee assembly should also be

checked for debris. a wash cycle should be initiated

before placing the SG on line, refer to the in Place

cleaning owner’s Manual for the start up operational

procedure.

!

NOTICE

Figure 11

Component Door and Power Pack Door Closed

Figure 12

Component Door Open and

Power Pack Door Closed

Figure 13

Component Door Closed and

Power Pack Door Open