10

revised 09/09

Smog-Hog

SG Series Model

6.1.3 PERFORM IN PLACE CLEANING

If the SG is equipped with In Place Cleaning a daily

wash cycle is required refer to In Place Cleaning

Owner’s Manual and Sequence of Operation

instructions. a typical seven day wash cycle would be

six day waterwash without detergent with the seven

day a detergent wash. The detergent wash frequency

can be increased up to everyday. the auto wash cycle

is initiated by a uaS time clock, with the wash cycle

sequencing, wash cycle times, and detergent frequency

through the uaS Main electrical Panel. a wash

cycle can be manually initiated, identical operation

as the auto wash cycle, for an additional wash cycle.

a wash cycle whether a manual or by time clock can

only be initiated with the SG off line. the wash cycle

frequency could be increased or decreased depending

on visual inspection of the components and high

voltage measurements. When the SG is placed on

line after a wash cycle, the power pack enclosure(s)

indicator light(s) may intermittently or continuously blink

for approximately 60 minutes. If this condition exceeds

60 minutes, refer to Section 10 troubleshooting.

6.1.4 MANUALLY CLEANING COMPONENTS,

CABINET AND OTHER EQUIPMENT AS REQUIRED.

the unit components should be manually cleaned one

to three month interval depending upon application/high

voltage measurements refer to Section 6.2.

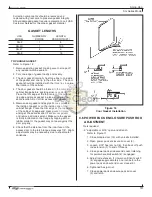

6.2 MANUAL CLEANING OF SMOG-HOG

COMPONENTS

there are a number of methods for manual cleaning,

certain key cleaning criteria contribute to the

effectiveness of every method. these include the type

of detergent, detergent strength, water temperature,

agitation/ impingement, duration, rinse procedure and

dry-out time.

6.2.1 TYPE OF DETERGENT

in general, the detergent used on most hydrocarbons

(e.g., oily residues) will be alkaline in nature. it is

extremely important that the detergent have a built-in

buffering agent to reduce aluminum deterioration.

6.2.2 DETERGENT STRENGTH

Detergent concentration in a mixture with water varies

with the application from 1:1 to 20:1 parts water to parts

detergent. for any contaminant condition, the best

course is to use a cleaning solution per the detergent

manufacturer’s directions. More or less detergent

may eventually be required for effective cleaning at

reasonable detergent cost. the recommended factory

detergent concentration is 5% (20:1).

CAUTION

Never mix caustic and alkaline detergents for

manual or in-place cleaning. Detergent mixing

could cause rapid heat release, gel formation

or some other undesirable condition. Complete

purging of system piping is necessary when

changing detergents.

6.2.3 WATER TEMPERATURE

Detergents can be up to twice as effective in hot water.

Hot water alone is very effective in softening built-up

residue. Water temperature should be 140°F to 170°F,

not to exceed 180°F.

6.2.4 AGITATION/IMPINGEMENT

these methods are virtually the same, with

impingement being the most extreme form of agitation.

Any liquid movement over built-up residue will remove

a layer, allowing detergent to work on the next layer. A

reduction in cleaning time duration usually results.

6.2.5 CLEANING CYCLE DURATION

In most cleaning methods, adequate time should be

allowed for the detergent to remove the contaminant

thoroughly. reaction time will vary depending on

detergent strength, temperature and agitation.

Guidelines for mixing, heating and expected results are

included on specification sheets for most detergents.

time is necessary for effective cleaning. Soaking may

seem slower and less effective than high impingement

and/or hot water above 180°F for cleaning action, so

personnel should be forewarned about using excessive

pressure or temperature to shortcut the cleaning

process. High pressure or stream spray cleaning until

plate edges are shiny is not effective. not only will

penetration to the cell core not occur, but warping and

bending of the plates may result as well. Patience and

thoroughness of cleaning best preserve the integrity of

the components in the long term. Soaking and gentle

rinsing provides for best results.

6.2.6 RINSE PROCEDURE

Cleaned components should be rinsed off quickly and

thoroughly to remove remaining contaminants. Some

detergent residue will remain if rinsing is not performed.

the residue may contribute to voltage bleed-down when

the unicell is placed in operation. also, even though the

detergent is “buffered” prolonged contact could cause

minor corrosion. Hot water should be used for rinsing.