12

revised 09/09

Smog-Hog

SG Series Model

9. PART REPLACEMENT

PROCEDURES AND ADjUSTMENTS

9.1 IONIzER WIRE REPLACEMENT

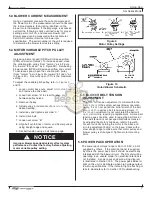

(REFER TO FIGURES 16 AND 17)

1. remove damaged wire from each spring.

2. replace spring if damaged or missing.

3. Loop one end of new wire over bottom spring. Pull

top wire loop with pliers over top spring.

4. release spring gently. Wire should now be taut

and centered.

NOTE:

if replacement wires are not available, remove

broken wires and tension springs from the

ionizer section. install unicell into the cabinet

until parts are available.

9.2 DOOR FEED-THRU INSULATORS

1. Place toggle switch in “off” position.

2. open power pack enclosure lid cover, perform

grounding procedure refer figures 14 and 15,

3. remove high voltage wire by removing #10-32

hex nuts.

4. remove insulator retaining nut.

5. open module door and remove the long screw

from the insulator.

6. remove the insulator from the interior of the

module door by using a hammer.

7. clean silicone sealant from module door surface.

8. install replacement insulator, reversing the above

procedure, and applying a thin coat of Silicone

sealant to base of insulator.

9.3 INDICATOR LIGHT

1. open the power pack enclosure lid cover.

2. Disconnect the red and black wires from the

indicator light which is connected to wires “9”

and “2”.

3. remove indicator light installation nut. the

indicator light located on each power pack

enclosure is polarity sensitive. for proper

operation, the two wires from the indicator

light should be connected as follows, red wire

connected to “9” wire from the power pack, black

wire connected to “2” wire from the power pack.

if the wires are reversed, the indicator light will

not illuminate.

9.4 BLOWER LUBRICATION

The blower bearings require lubrication at a 2 to 3

month interval (petroleum lubricant lithium nLGi grade

2 grease). the bearings should be lubricated with the

blower in operation. a hand operated grease gun is

required performing one to two injections slowly, do

not exceed two injections. Excessive injections/grease

will cause bearing seal failure, contributing to bearing

failure.

Figure 16

Attaching

New Ionizer Wire

Figure 17

Correct

Ionizer Wire Position

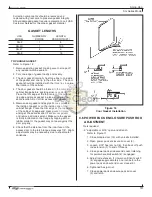

9.5 COMPONENT ACCESS DOOR GASKET

REPLACEMENT

as shipped from uaS, gasketed component access

doors have been carefully sealed against leakage of

liquids from the air cleaner cabinet. Should leakage

occur, slight adjustment of the latch paws on the back

of the door handles may solve the problem. However,

extreme care should be exercised in compressing door

gasket beyond its design limits. Before adjusting for

gasket deflection, check for the following:

1. Door or cabinet damage.

2. Deformed or torn gasket.

3. Leakage from some other source.