16

revised 09/09

Smog-Hog

SG Series Model

STEP 2

PROBLEM: Indicator light is flashing.

PROCEDURE: Checking the unicell

components

Do not proceed with step (2) until step (1) is completed.

the following steps are the process of elimination in

identifying the problems to the ionizer/collector cell

circuit.

there are four conditions which could occur with a

flashing indicator light.

1. the high voltages are below specifications to the

ionizer and or the collector cell circuit(s).

2. there is an arcing condition to the ionizer and or

collector cell circuit(s).

3. there is a dead short condition.

4. the power pack has failed. refer to step 1.

(a)

Place the toggle switch in the off position, and

open power pack lid door. Disconnect high voltage

wire #8 to the ionizer connector with high voltage wire

#7 (collector) connected on the power pack and place

toggle switch in the on position and engage interlock

switch. the indicator light should be illuminated. if so,

the cell circuit is operational proceed to (b). if indicator

light is flashing perform the following:

• Place toggle switch in the off position, open

component door, and remove the unicell(s).

• Place toggle switch in the on position, and engage

interlock switch. the indicator light should be

illuminated. if the indicator light is illuminated the

problem is within the collector cell section. if the

indicator light is flashing the problem is the high

voltage door feed through insulator (dirty, cracked,

carbon tracking) and or the high voltage wire

(broken wire or wire insulation has deteriorated

causing a dead short condition).

Parts should be replaced as required.

inspect the unicell(s) for the following:

COLLECTOR CELL CONDITIONS CAUSING FAILURE

• Dirty collector cell(s) (contaminant build up bridging

the cell plates and or on cell triangular insulators)

requiring manual cleaning.

• “Wet” collector cell(s), not properly dried after a

wash cycle or manual cleaning procedure, use

compressed air to accelerate the drying time.

• Deformed collector cell contact springs contacting a

“grounded surface”.

• Misaligned contact springs (contacting a grounded

surface) between the outer and inner most cells if

module is equipped with two unicells and or at high

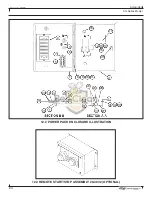

voltage feed through insulators. refer to figure 20.

• Bent cell plate(s) contacting the opposing cell

plate(s).

• Warped cell plate(s) which could be due to high

duct operating temperature, consult uaS.

• Carbon tracking to the cell high voltage feed

through insulator and or cell triangular insulators,

imbedded black streak which cannot be removed

by cleaning (replace insulator.)

• Surface oxidation to unicell component requiring

a replacement.

• Unicell is structurally weak, loose steel rivets,

deterioration to cell plate spacers or paper thin cell

plates due to utilizing the improper detergent.

Parts should be replaced as required, install unicell(s).

Sometimes a flashing indicator light will clear itself

by removing the unicell(s) from the module and then

installing the unicell(s) back into the module.

the Bench test Procedure will determine which

unicell(s) are causing a flashing indicator light, refer to

Section 10.3.

Place toggle switch in the off position; connect all wires

which have been disconnected and install unicell(s).

(b)

indicator light is illuminated with the high voltage

wire #7 connected to the collector cell connector on the

power pack. Place toggle switch in the off position and

connect high voltage wire #8 to the ionizer connector

on the power pack. Place the toggle switch to the on

position and engage the interlock switch.

the indicator light should be illuminated? if so, the

unicell(s) are operational. if the indicator light is flashing

perform the following:

• Place power in the off position, open the

component door, and remove unicell(s).

• Place toggle switch in the on position and engage

interlock switch. if the indicator light is illuminated

the problem is within the ionizer section. if the

indicator light is flashing the problem is the high

voltage door feed through insulator (dirty, cracked,

carbon tracking) and or the hv wire (broken wire

or wire insulation has deteriorated causing a dead

short condition).

Parts should be replaced as required, install unicell(s).

inspect the unicell(s) for the following:

IONIzER CONDITIONS CAUSING FAILURE

• Dirty ionizer(s) (contaminant build up) requiring

manual cleaning.

• “Wet” ionizer(s), not properly dried after a

wash cycle or manual cleaning procedure, use

compressed air to accelerate the drying time.

• Deformed ionizer contact springs contacting a

“grounded surface.”

• Misaligned contact springs (contacting a grounded

surface) between the outer and inner most ionizer,

if module is equipped with two unicells, or at the

ionizer high voltage feed through insulator. refer

to figure 20.