18 | Art.-nr.:

616711-A

Ubifl ux Vigor W225 | 19

5.5.3 Connecting the eBus connector

For connecting an eBus connector, the 2-pole detachable (green) connector X17 is located at the rear of

the display cap ( Exploded view of appliance page 10). The eBus protocol may for instance be used to

connect the Air Control ( Connecting Air Control page 42). Because of polarity sensitivity, always connect

contacts correctly; the appliance will not work if these contacts have been interchanged!

The following functions can also be connected to the eBUS connector: the optionally available CO2 sensor(s)

( connecting CO2 sensor(s) page 44) or an additional eBUS pre-heater ( connecting pre-heater page

47) or post-heater ( connecting post-heater page 46).

5.5.4 24 volt connection

On the X16 & X18 connector of the basic pcb, 24 volt is available. Connector X-16 is for 24 volt connection of

the optional Plus pcb. For position connection (black) connector X16 & X18 ( Electrical diagram page 35).

Maximum current reduction at plug X16 and X18 is 5 VA per connection.

5.5.5 Connecting humidity sensor

The optional humidity sensor has to be connected onto the the X07 connection of the basic pcb. For this,

use the cable supplied with the humidity sensor. In order to connect the humidity sensor, the plastic cover

above the control has to be taken off , after which the X07 connection is accessible.

For connecting the humidity sensor, see Connecting humidity sensor page 43.

5.5.6 Connection external Bus

The Modbus/ external bus (red) connector X15 can for example be used for coupling appliances ( Coupling

appliances using external Bus page 19).

The function of this connector can be adjusted using step number 14.1 to 14.4 in the settings menu.

If the appliance is fi tted with a Plus pcb, then this red connector X15 is also in use for connecting the Plus

pcb; several cables then have to be connected onto this connector X15.

5.5.7 Connecting "signal output” connector

The blue 2-pole screw connector X19 ( Electrical diagram page 35). This connection is used to give a

fi lter message or fault message.

If a fi lter or fault message is given in the appliance a contact is closed at connection X19. The operation of

this is set by following step number 16.1.

5.5.8 ModBus Connection

The appliance can be connected with a ModBus system such as a building management system.

Using the (red) 3-pole connector X15 (or with the Plus version the red connector X06 on the UWA2-E

pcb) a connection can be made between the appliance and the ModBus system; ( Electrical diagram

page 35) for the right connection.

For the correct setting of the jumpers X12, X121 & X122 see the explanation given with electrical diagram

( Electrical diagram page 35); for more information and the correct modBus settings see the separate

Modbus manual on the website!

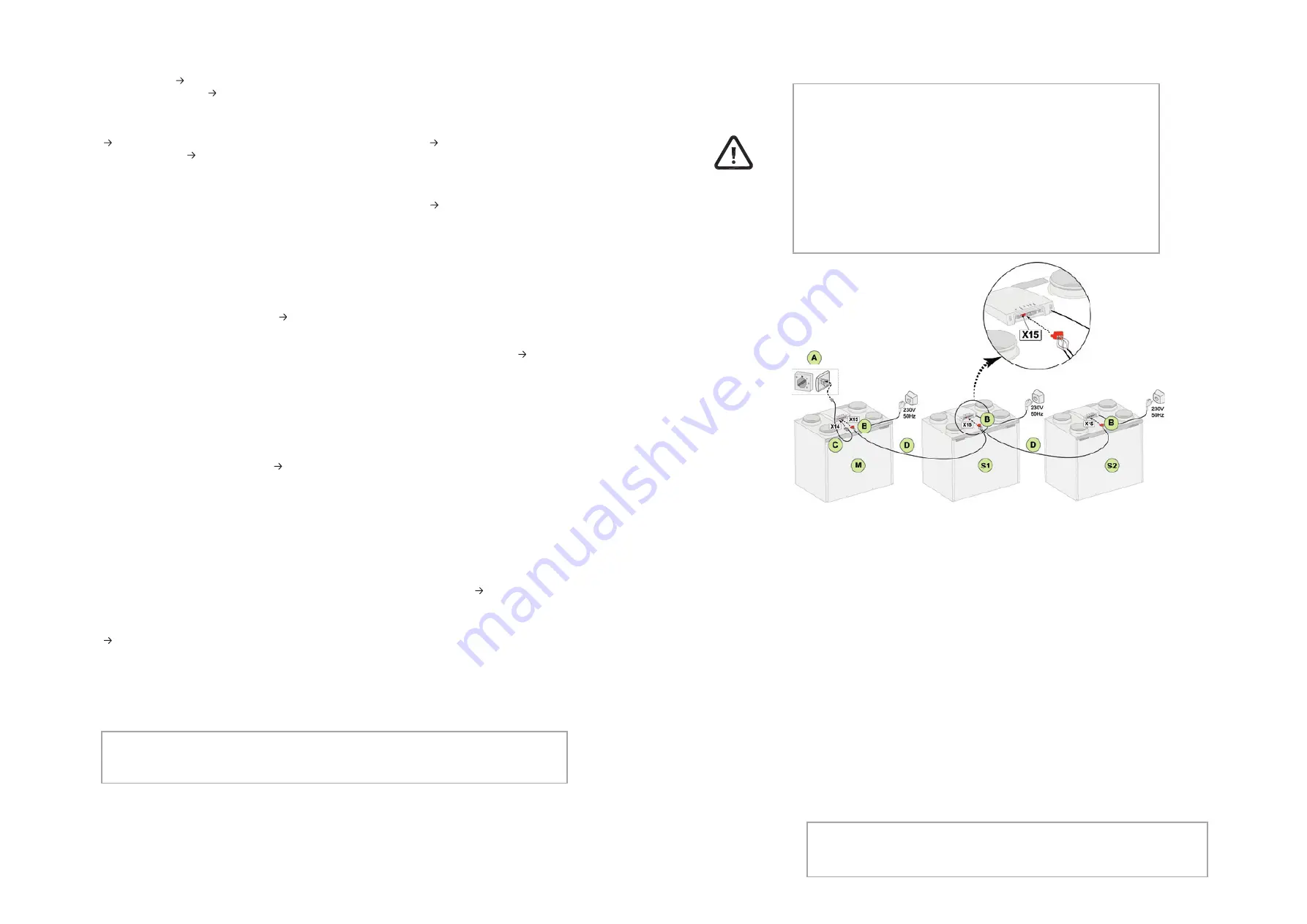

5.5.9 Coupling appliances using external Bus

Note:

When ModBus is active, the ventilation mode cannot be changed using the display or, if

applicable, the connected multiple switch! Also any connected humidity sensor will not function.

Note:

Any accessory such as moisture sensor, position switch, extension board or any

eBus device must be connected to the Ubifl ux Vigor W225 master appliance only.

Important:

Because of polarity sensitivity, always connect the external Bus contacts X15-

1 with one another, and the contacts X15-2 and the contacts X15-3 with one

another. Never connect X15-1, X15-2 or X15-3 with one another!

Comment:

If a Plus pcb has been installed; several cables would have to be

connected onto the X-15 connector.

Note:

When the total length of the external Bus cables is longer than 10 m, then

use a twisted-pair cable for connection X15-2 & X15-3 (a twisted pair cable is

also preferred with shorter lengths)!

A = Multiple switch

B = 3-pole connector red

C = Modular cable

D = 3-core low voltage cable

M = Master appliance (For example a Ubifl ux Vigor appliance type 4-0)

S1 / S2 = Slave appliances (For example a Ubifl ux Vigor appliance type 4-0); connect max.

of 10 appliances via externalBus

All Ubifl ux Vigor W225 appliances have the same air fl ow rate as the appliance that is set

as "Master". The fault messages of

all

appliances are shown on the display of the master

appliance. When using a Air Control or the Home, always connect this to the Master.

After connecting the cables confi gure each Ubifl ux Vigor W225 appliance:

|

Enable "externalBus" in menu 14.1 "Type of Bus connection" where shortly after the

network symbol appears.

|

Confi gure each slave in menu 8.1 "Appliance setting slave 1, slave 2 etc where shortly

after the M symbol appears on the master appliance and S1, S2 symbol on slave

appliances

|

Power down and up all appliances

For M (master):

Step no. 8.1 - Master

Step no. 14.1 - externalBus

For S1 (Slave 1):

Step no. 8.1 - Slave

Step no. 14.1 - externalBus

For S2 (Slave 2):

Step no. 8.1 - Slave

Step no. 14.1 - externalBus