Warning!

When working on the appliance, always fi rst take the voltage from the appliance by pulling

the power plug.

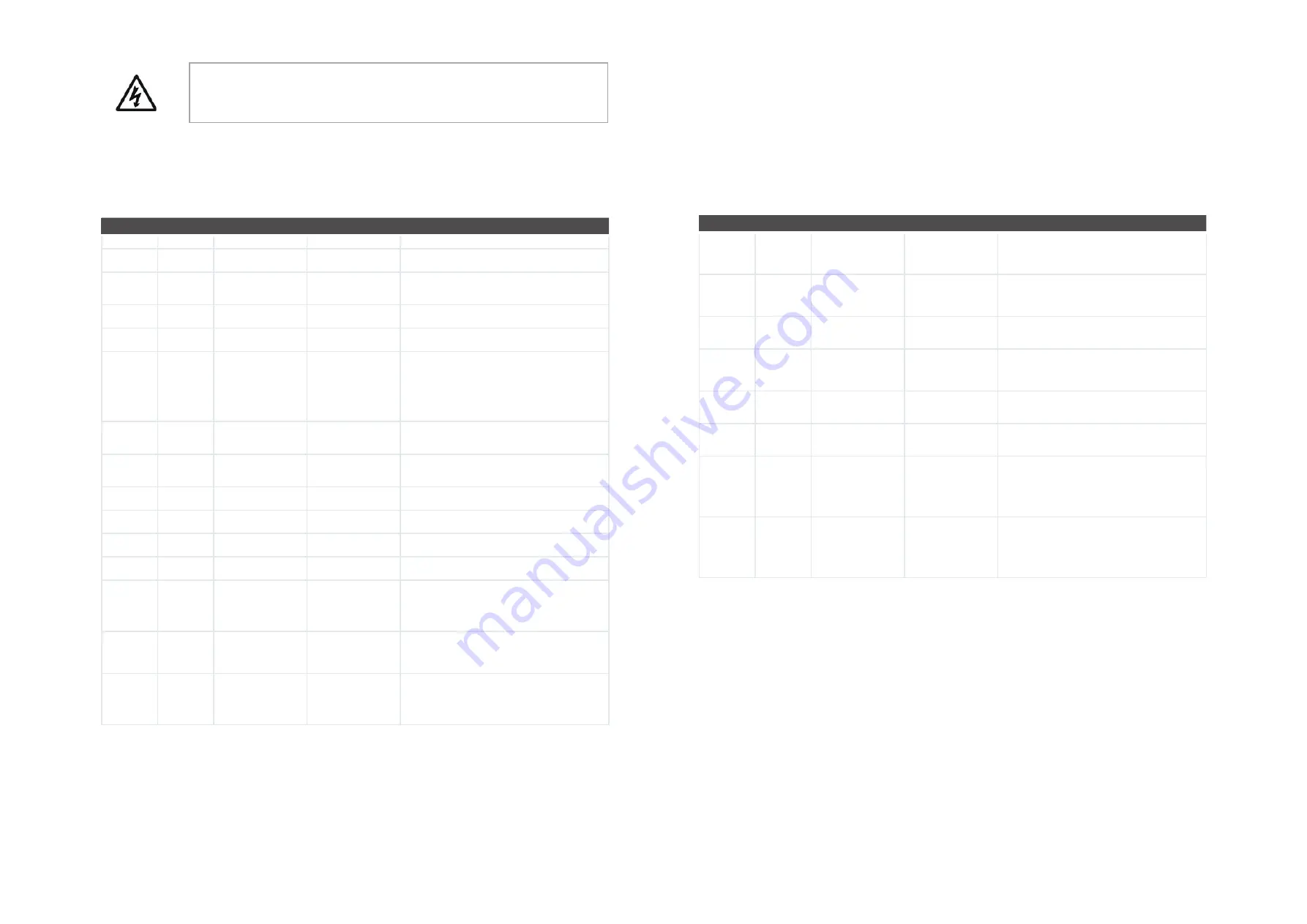

In the table below the locking faults are marked with an * after the fault number. The display shows a brief expla-

nation of this fault code. If there is reference to the "Standby" mode of the appliance, then both fans are shut down

but there is still something shown on the display of the appliance.

Faultcode

Subcode

Cause

Appliance action

User action

E190

E1000

Self-test not good

No action

E152*

E1001 *

Flash memory faulty

Stop appliance if

possible

Replace basic pcb UWA2-B

E153

E1002

EEPROM memory

defective

Appliance goes to

factory setting; fan

setting 2

Replace basic pcb UWA2-B

E105

E1011

Requested supply fl ow

rate is not achieved

None

Clean or replace fi lters

Check that ducts are not blocked

E104

E1012

Requested exhaust fl ow

rate is not achieved

None

Clean or replace fi lters

Check that ducts are not blocked

E000*

E1013 *

Temperature of outside

air too high

Appliance goes to

standby

Depending on the situation:

In the event of warm weather and a supply directly below

the tiles, wait until the air has cooled or install a roof sleeve

instead of duct under the tiles

In the event of cold weather or when there is no air from

below the tiles, take the voltage from the appliance and

replace air temperature sensor (NTC)

E105*

E1100 *

Supply fan defective;

general message

Appliance goes to

standby

Replace supply fan

Fault is reset automatically when voltage is put back on

appliance.

E104*

E1120 *

Exhaust fan defective;

general fault message

Appliance goes to

standby

Replace exhaust fan

Fault is reset automatically when voltage is put back on

appliance.

E103

E1200

Bypass defective;

general fault message

None

Check wiring

Replace bypass or wiring harness

E106*

E1300 *

Sensor NTC1 defective;

general fault

Appliance goes to

standby

Check wiring

Replace NTC sensor or replace wiring

E111

E1400

RHT sensor 1 defective;

general message

No humidity control

Check wiring

Replace RHT sensor or replace wiring

E114

E1500

Multiple switch defective;

general fault

Appliance goes

to mode 1

Replace multiple switch

E113

E1600

Internal preheater

defective; general fault

message

Frost protection goes to

imbalance mode

Check fuses

Check wiring; replace if damaged and replace otherwise

the internal preheater

Fault is automatically reset when the voltage is put back on

the appliance.

E130

E1800

Relay output 1 defective;

general fault

Signal output not

available

Take voltage from appliance

Replace UWA2-B pcb

Fault is automatically reset when voltage is again put back

on appliance

E1155

E2000

Touchscreen fault;

general fault

message

Fault codes only visible

when using service tool

Check wiring to touchscreen; replace wiring

if damaged; replace touchscreen if fault still occurs replace

UWA2-B

Fault is automatically reset when voltage is again put back

on appliance

Foutcode

Subcode

Oorzaak

Actie toestel

Actie gebruiker

E120

E2100

EBus fault; general fault

message

Air Control and other

accessories connected

to eBus do not work.

Appliance is working

Check wiring to accessories/ Air Control

Check accessories/ Air Control and replace if defective

If there is still a fault after this: Take voltage from appliance

and replace basic pcb UWA2-B

E121

E2200

externalBus general fault

message

Air Control and other

accessories do not work.

Appliance is working

Check wiring to accessories/ Air Control

Check accessories/ Air Control and replace if defective

If there is still a fault after this: Take voltage from appliance

and replace basic pcb UWA2-B

E122

E2300

Internal ModBus fault;

general fault message

Appliance goes to

standby

Check wiring and connections to UWA2-B and the fans

Replace cable harness if damaged; Then exchange

UWA2B, exhaust fan and supply fan

E123

E2400

Internal ModBus fault;

general fault message

Operation via Modbus

does not work

Check cabling of accessories; replace if damaged

Check accessories; replace if defective

If fault still occurs: Take voltage from appliance and

replace UWA2-B basic pcb

E124

E2500

USB port general fault

message

USB interface not usable

Replace USB accessory

If the fault is not remedied after this: take the voltage from

the appliance and replace UWA2-B basic pcb

E170

E2600

One or more CO

2

sensor(en) defective;

general fault message

Appliance is working;

no CO

2

regulation

Check cabling and CO

2

sensor(s); replace if damaged

Check CO

2

sensor(s); replace if defective

E171

E2700

External preheater or

fuse defective; general

fault message

No preheater / comfort

control responds

diff erently

Uncouple preheater and check preheater fuse; replace

fuse if defective

Has the fault not yet been remedied:

Replace external preheater

Put voltage back on appliance

Fault has automatically been reset

E172

E2800

External postheater or

fuse defective; general

fault message

No postheater / comfort

control responds

diff erently

Uncouple postheater and check postheater fuse; replace

fuse if defective

Has the fault not yet been remedied:

Replace external postheater

Put voltage back on appliance

Fault has automatically been reset

28 | Art.-nr.:

616711-A

Ubifl ux Vigor W225 | 29