www.beer-co.com

37

AURORA

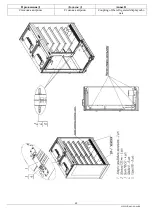

5. ARRANGEMENT REQUIREMENTS

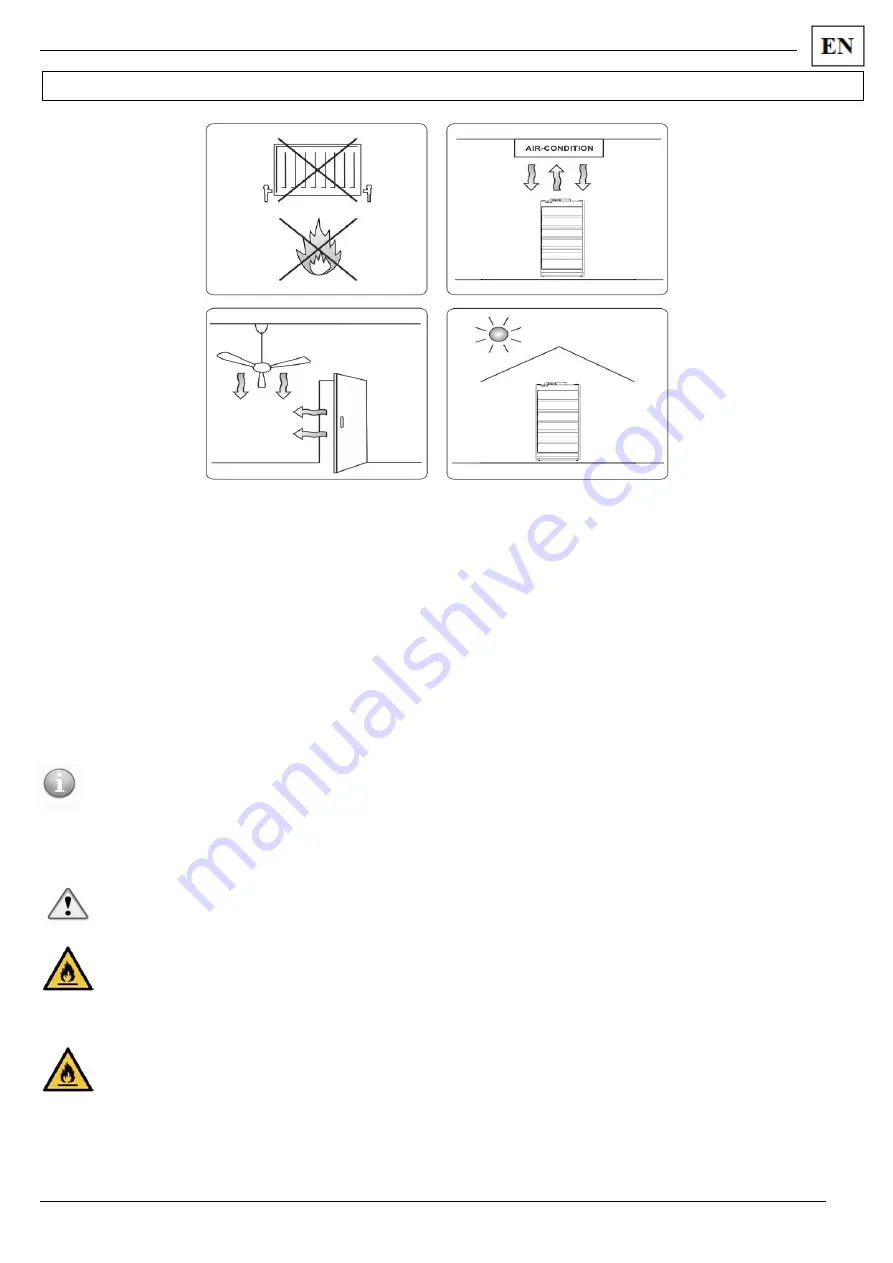

Figure 3 – Arrangement of the refrigerated display cabinets

Install the refrigerated display cabinets on an even horizontal surface, if necessary, use adjustable legs to level up

the product. The refrigerated display cabinets should not tilt, incomplete alignment can result in deterioration of the prod-

uct work.

If the refrigerated display cabinets has wheels, they must be fixed after the product installation.

DO NOT

install the refrigerated display cabinets in the following places (Fig. 3):

•

in close proximity to heat sources (e.g. heating batteries, equipment for food heating or cooking);

•

near the doors or in a draft caused by opening of the doors or windows;

•

in areas where strong air movement is possible (e.g. outlets of climatic, ventilation and heating systems);

•

exposed to direct sunlight.

Air movement at a speed of over 0,2 m/sec in the area of the refrigerated display cabinets installation deteriorates

its operating characteristics.

Install the refrigerated display cabinets in such a way as to ensure free air circulation in the unit compart-

ment. Ensure a free zone of no less than 15 cm from the back wall of the refrigerated display cabinets to discharge warm

air from the condenser.

DO NOT

place in the unit compartment any foreign objects that impede normal cooling of the refrigerating unit.

When arranging the refrigerated display cabinets at fuels and lubricants facilities, it must be installed and

operating rules at fuels and lubricants facilities. According to the requirements of UL 471, the refrigerated

display cabinets charged with a highly flammable refrigerant must be arranged at the level of no less than 18

inches (450 mm)0 above ground level at fuels and lubricants facilities.

According to the requirements of EN 378-1-2014, for refrigerated display cabinets charged with a flammable

refrigerant (e.g. R290) a minimum volume of premises is specified based on the lower flammability limit. For

example, the minimum volume of the room where the refrigerated display cabinets charged with R290 can be

arranged is 12,5 m

3

for every 100 g of the charged refrigerant. If a number of refrigerated display cabinetss

charged with a flammable refrigerant are located in one room, their charge values are summed up and the

volume of the room is selected accoding to their total charge (charge values are indicated on the nameplates).

In case of non-compliance with the refrigerated display cabinets installation rules, its operating characteristics may

differ from those stated.

Summary of Contents for AURORA

Page 1: ......

Page 4: ...4 www beer co com AURORA...

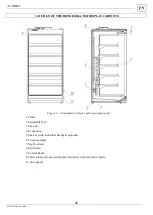

Page 7: ...www beer co com 7 AURORA 3 2 1 2 3 4 5 6 7 8 9 10 11...

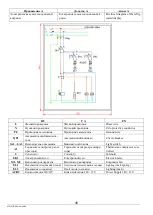

Page 8: ...8 www beer co com AURORA 4 IEC 60529 2013 IEC 61140 2012 80 100...

Page 9: ...www beer co com 9 AURORA 5 3 3 0 2 15 UL 471 18 450...

Page 11: ...www beer co com 11 AURORA 4 10 10 4 8 4 6 2 10 1 5 2 1...

Page 13: ...www beer co com 13 AURORA 12 3 3 3...

Page 14: ...14 www beer co com AURORA 13 4 4 6...

Page 15: ...www beer co com 15 AURORA 15 3 16 25 55 80 16 www beer co com...

Page 18: ...18 www beer co com AURORA...

Page 21: ...www beer co com 21 AURORA 3 2 1 2 3 4 5 6 7 8 9 10 11...

Page 22: ...22 www beer co com AURORA 4 IEC 60529 2013 IEC 61140 2012 80 100...

Page 23: ...www beer co com 23 AURORA 5 3 3 0 2 15 UL 471 18 450...

Page 25: ...www beer co com 25 AURORA 4 10 10 4 8 4 6 2 10 1 5 2 1...

Page 27: ...www beer co com 27 AURORA 2 12 3 3 3...

Page 28: ...28 www beer co com AURORA 13 4 4 6...

Page 29: ...www beer co com 29 AURORA 15 3 16 25 55 80 17 www beer co com...

Page 48: ...48 www beer co com Annex D Coupling of the refrigerated display cabi nets...

Page 49: ...www beer co com 49...

Page 50: ...50 www beer co com...

Page 51: ...www beer co com 51...