10 — English

OPERATION

The recessed blade-support roller ensures accurate cutting. Its

hard-wearing die-cast aluminum casing helps protect against

overheating.

The wire blade guard helps protect the operator from accidental

contact with the saw blade.

Rest the front of the saw base on the workpiece and align cutting

edge of the blade with the line on your workpiece. Start the

saw and move it forward on the work surface. Apply downward

pressure to keep the saw steady and only enough forward

pressure to keep the blade cutting. Do not force the saw. Forcing

the saw may overheat the motor and break saw blades. Broken

saw blades must be replaced with new saw blades.

Orbital Motion

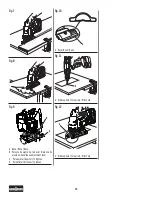

See Figure 6, page 15.

The blade of the saw cuts in orbital motion. This may be adjusted

for faster, more efficient cutting. With orbital motion, the blade

cuts through your work in the upstroke but does not drag across

your work in the downstroke.

The orbital adjustment knob allows you to select five orbital

settings to cut materials of varying thickness and density. The

higher settings should be used when fast cutting in soft material

is desired. The lower settings should be used for slower cutting

in materials with more resistance.

Straight Cutting

See Figure 7, page 16.

A straight cut can be made by clamping a piece of wood or

straightedge to the workpiece and guiding the edge of the

saw against it. Make the cut from one direction only; don’t cut

halfway and complete the cut from the opposite end.

NOTE:

Do not use the anti-splintering insert when making bevel

cuts, scroll cuts, plunge cuts, and when cutting metal.

Scroll Cutting

See Figure 8, page 16.

Scroll cuts can be made with the jig saw by guiding the direction

of the cut with applied pressure on the handle as shown.

WARNING:

Excessive side pressure to the blade could result in broken

blades or damage to the material being cut.

Angle Cutting (Bevel Cutting)

See Figures 9 - 10, page 16.

With the tool-free shoe adjustment, you can make quick changes

to the bevel setting. The shoe can be angled 45˚ left or right for

bevel cutting, with positive stops in 15˚ increments. A protractor

is recommended when accurate cuts are required.

•

Remove the battery pack from the tool.

•

Push the shoe adjustment lever forward to loosen the shoe.

•

Slide the shoe forward and to the left or right. Select the

desired degree of bevel by aligning the tab on the motor

housing with the appropriate notch on the rear of the shoe.

•

Slide the shoe back (toward the rear of the tool) to fit the tab

into the notch.

•

Push the shoe adjustment lever firmly back into place. Make

sure that the shoe is properly set before starting the jig saw.

•

Reinstall the battery pack.

NOTE:

When making a set-up for accurate cuts with a

protractor, or for angles other than the preset 15° increments,

the positive stop notches on the rear of the shoe are not used.

Plunge Cutting

See Figures 11 - 12, page 16.

WARNING:

To avoid loss of control, broken blades, or damage to the

material being cut, always use extreme caution when making

plunge cuts. We do not recommend plunge cutting on materials

other than wood.

Summary of Contents for UJS04BRA

Page 36: ...13 English NOTES ...