UBI EasyCoder 401 Linerless – Installation Instructions

3

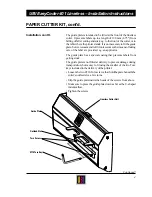

• Tilt the cutter unit upwards until it locks into place. If the cutter

does not lock properly, the hinges of the cutter unit may need to

be adjusted using a #T10 Torx screwdriver.

• Switch on power. The cutter will perform an idle cycle in order to

occupy its home position.

• Use e.g. the Terminal Setup in UBI Shell or setup files to change

the startadjust value to -294 and the stopadjust value to +250.

Setup files should be composed like this:

"DETECTION,FEEDADJ,STARTADJ,-294"

"DETECTION,FEEDADJ,STOPADJ,250"

• Tilt down the cutter and thread the paper through the cutter unit

between the paper guides (see illustration above). Then tilt up the

cutter again and lock it in closed position. Check that the printhead

is lowered. Now the printer is converted to EC 401 LLC standard

and is ready for operation after the guide plate has been installed,

as described on next page.

Note!

If the cutter do not operate properly after installation,

check the instructions on page 5.

PAPER CUTTER KIT, cont'd.

Continued!

Installation, cont'd.

Hinge

Hinge

Paper Guides