UBI EasyCoder 401 Linerless – Installation Instructions

4

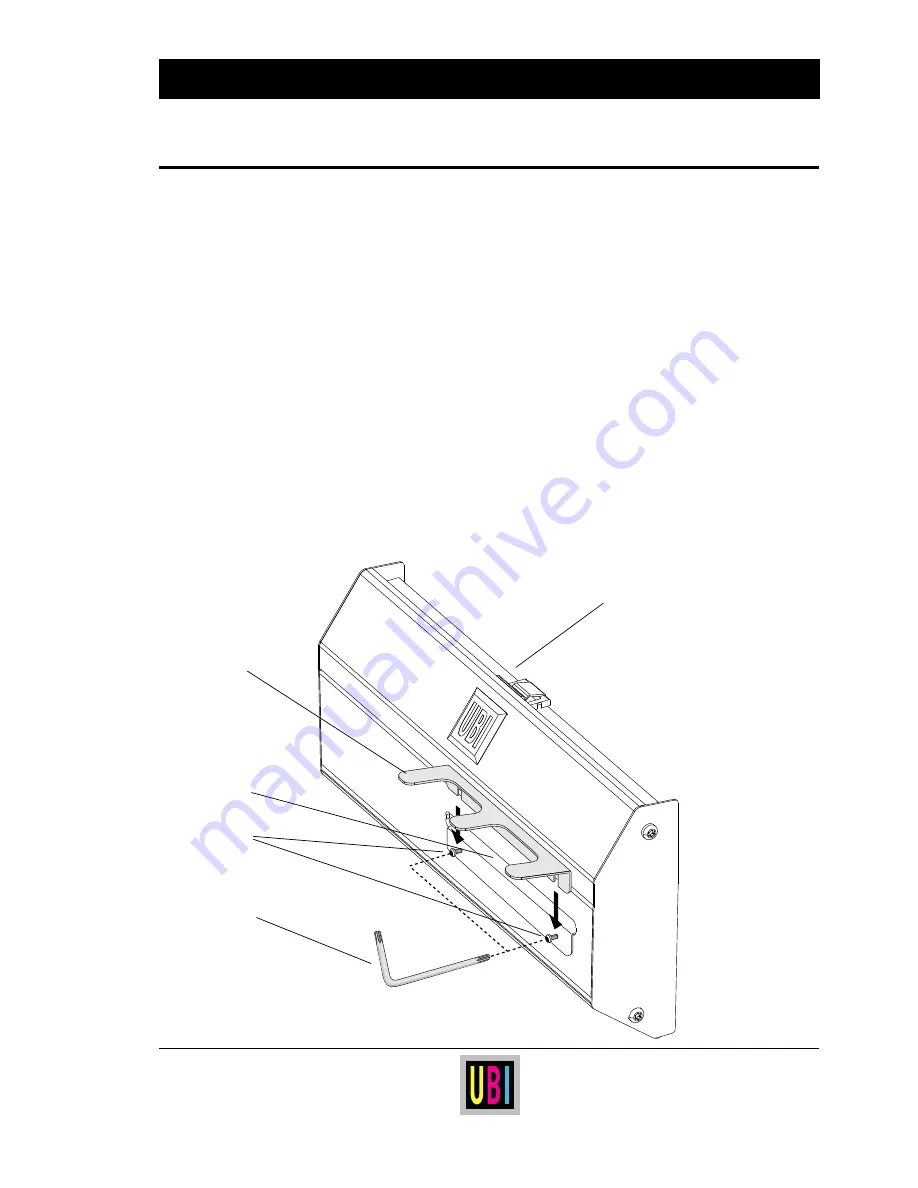

PAPER CUTTER KIT, cont'd.

Installation, cont'd.

The guide plate is intended to be fitted at the front of the linerless

cutter. It prevents labels up to a length of 120 mm (4.75") from

falling off after cutting and stick e.g. to the front of the cutter, or to

the table where the printer stands. It is not necessary to fit the guide

plate, but we recommend to fit it unless some other means of taking

care of the label are provided, e.g. an applicator.

The guide plate has a special coating that prevents labels from

getting stuck.

The guide plate is not fitted at delivery to prevent damage during

transportation, but is easy to fit using the smaller of the two Torx

keys included in the delivery of the printer:

• Loosen the two #T10 Torx screws, that hold the plate beneath the

cutter's outfeed slot, a few turns.

• Slip the guide plate inside the heads of the screws from above.

• Make sure to press the guide plate down as far as the U-shaped

indents allow.

• Tighten the screws.

Linerless Cutter Unit

Guide Plate

Outfeed Slot

#T10 Torx Key

Torx Screws

Continued!