UBI EasyCoder 401 Linerless – Installation Instructions

8

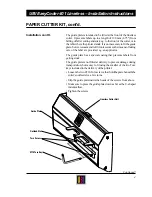

PAPER CUTTER KIT, cont'd.

The cutter mechanism consists of a rotating shear and a spring-

loaded anvil blade. To prevent the adhesive to stick to the cutting

parts, the rotating shear is lubricated with a thin film of silicon oil

at each cutting cycle, and the anvil blade is provided with a special

“non-stick” coating. Nevertheless, regular cleaning from adhesive

residue at the cutting edge of the anvil blade at an interval of

approximately 50,000 cuts is essential for troublefree operation.

Proceed as follows:

• Fold down the cutter. Be careful not to bend the guide plate, if

fitted.

• Disconnect the spring-loaded brace from the arm at the side

opposite to the motor and fold back the anvil blade. A microswitch

prevents the cutter from being operated while the anvil blade is in

open position.

• Soak a cotton swab with WD-40 multi-spray (or similar)

1

and rub

it against the cutting edge of the anvil blade to dissolve any

adhesive residue.

• Inspect the interior of the cutter for possible shreds of labels,

adhesive residue and similar. If necessary, clean using a cleaning

card or a cotton swab soaked with WD-40.

• Close the anvil blade and lock the arm with the brace.

• Fold up the cutter and the printer is ready for operation.

Cleaning

CAUTION!

WD-40 is an anti-corrosion spray

lubricant manufactured by WD-40

Company Ltd., Milton Keynes, England,

which contains 50% alifatic petroleum

distillate. It is highly flammable and

may be harmful if inhaled or consumed

and at prolonged skin contact. Before

use, carefully read the warning text on

the container.

Arm

Brace

Anvil Blade

Cotton Swab

w. WD-40

1

1

/. In food industry and retail applications

subject to specific regulations, the WD-

40 could be replaced with a pure consum-

able vegetable oil. After dissolving the

residue, carefully wipe clean the anvil

blade.