46

UBI EasyCoder 501 – Technical Manual

PRINTING PRINCIPLES

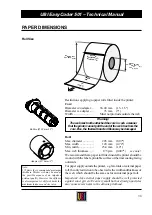

The printing is produced by the thermal printhead, which consists

of a line of very small, closely spaced resistors on a ceramic tile

fitted across the paper web. When a current is led through the

resistors, commonly called “dots,” these will be heated very

quickly. The heating is controlled by a powerful 32-bit microproc-

essor. When the current is shut off, the dots cool down just as fast.

All EasyCoder 501 printer models can use the direct thermal

printing method. The method requires a special paper coated with

a thin layer of heat-sensitive chemicals. As the paper is fed past the

dots, the heat from the dots will make the chemicals react, produc-

ing a dark salt, which makes up the imprint under each dot.

The thermal transfer printing method requires that the printer is

fitted with a special mechanism in which a special “ink”-coated

transfer ribbon is fed between the printhead and the receiving face

material, e.g. plain paper.

When the ribbon is heated by the dots on the printhead, the “ink”

melts and sticks to the receiving face material (e.g. paper), where the

ink immediately becomes solid again, producing a black spot. In

fact, the “ink” is a mixture of colour pigment and wax or resin that

melts at temperatures well above room temperature. Thus, a

transfer ribbon will not smudge the fingers of the operator, neither

before nor after printing. Printed labels do not smudge other objects,

but if an unfortunate combination of ribbon type and face material

is used, the printout may become smeared by extensive rubbing.

The thermal transfer method allows a wide range of face materials

to be printed upon, e.g. papers, boards, plastics, foils etc., provided

a transfer ribbon suited for the face material in question is used.

General Information

Direct Thermal Printing

Thermal Transfer Printing