72

UBI EasyCoder 501 – Technical Manual

RIBBON SAVE DEVICE, cont'd.

Transfer Ribbons

General Purpose (GP) ribbons are coated with a wax-based “ink”

that is more subject to smearing than the wax/resin-based “ink” of

High Performance (HP) ribbons. Certain combinations of GP

ribbons and thick and/or coarse receiving paper in connection with

Ribbon Save may result in a somewhat smudged printout quality.

As a possible remedy, a change to HP ribbons is recommended.

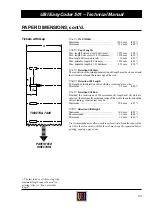

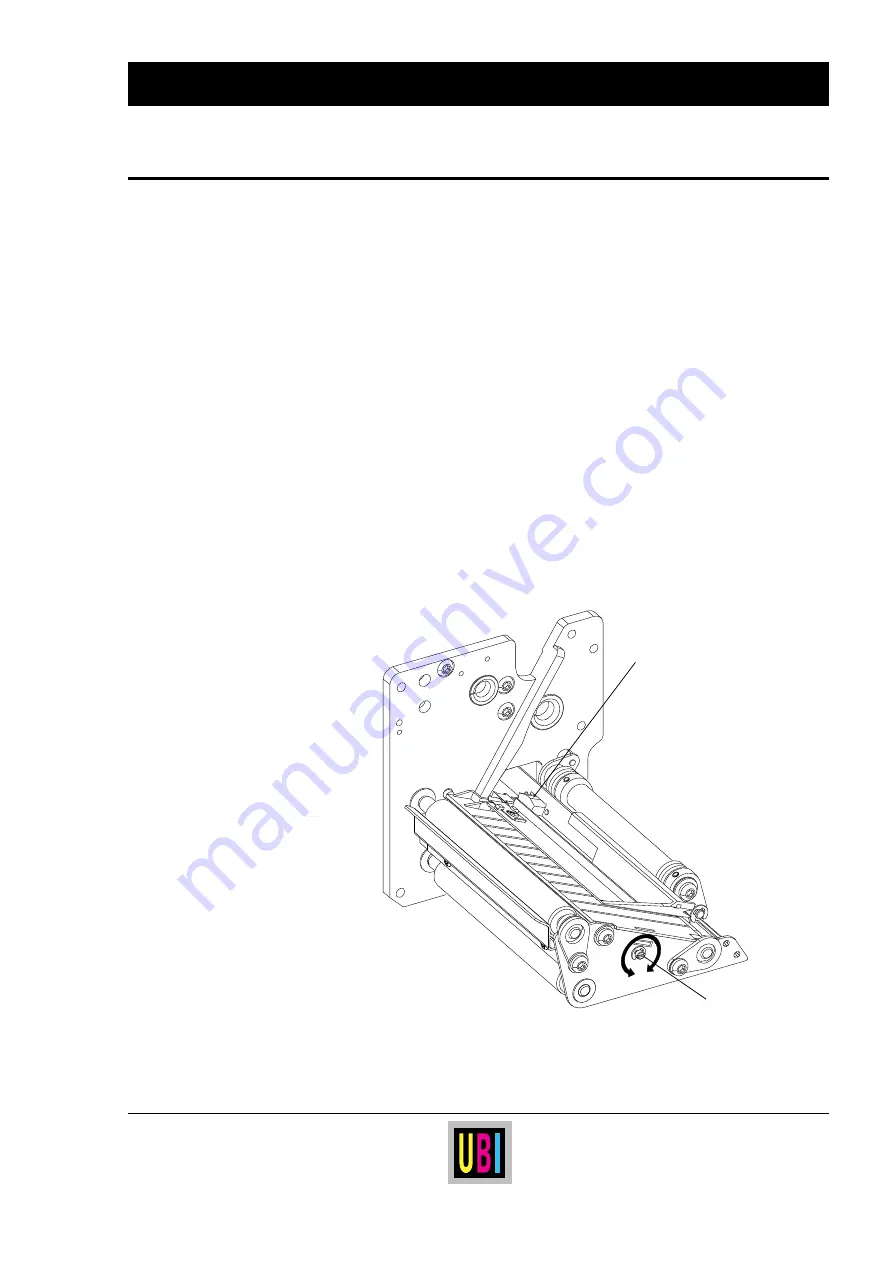

In printers fitted with a ribbon save device, the label stop/black mark

sensor (LSS) is laterally adjusted by means of a screw protruding

through the outer lower gable. Turning the screw clockwise will

move the LSS inwards and vice versa. The position of the LSS in

relation to the paper is best checked by looking head on into the print

unit when the printhead is lifted. Align the centrepoint of the V-

shaped upper sensor with the centre of the gaps to be detected.

The linear markings on the lower guide plate can also be used for

positioning of the LSS as they are spaced with an interval of exactly

1 cm (0.39") from the edge that guides the paper. This method is

especially useful for black marks (measure the lateral position of the

black marks with a ruler).

LSS Adjustment

OUT

IN

Adjustment Screw

Upper part of the print unit omitted to give a better view!

Upper Sensor

Continued!