8

7.3 PULSATION

DAMPENER

(ACCUMULATOR)

Before starting the Pump, verify the air pressure in the accumulator, if present.

This operation may be carried out, with the Pump off, connecting an air source to the inflation valve.

The air pressure should be checked periodically.

Using the Pump without air in the accumulator may cause system malfunctioning, damage the

accumulator diaphragm or the whole Pump.

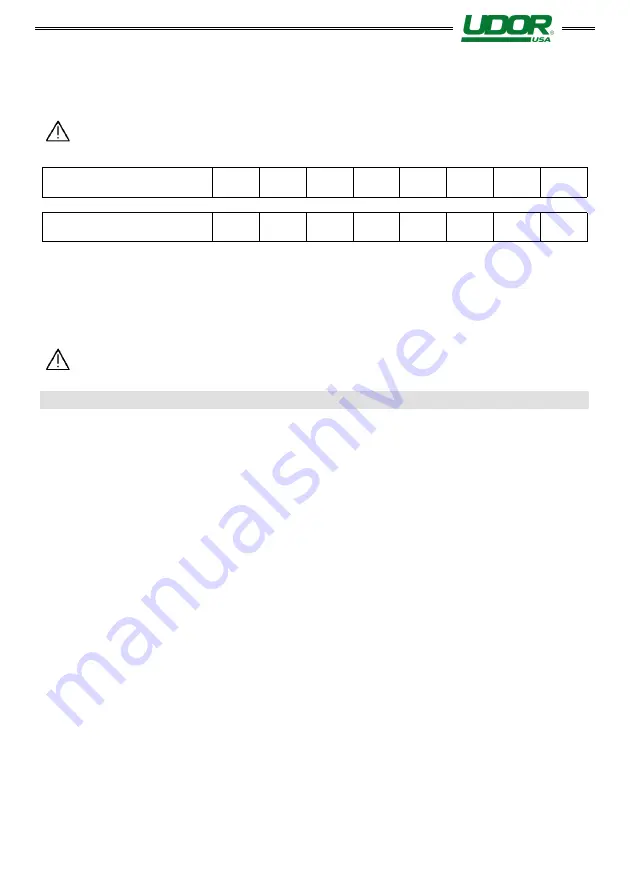

The accumulator’s air pressure varies according to the Pump’s operating pressure:

Pump Working Pressure

bar

PSI

2

29

5

72

10

145

20

290

30

435

40

580

50

725

Accumulator Pressure

bar

PSI

1

15

2

29

4

58

5

72

6

87

7

102

8

116

UDOR normally inflates the Pumps pulsation dampener at a pressure of 5 bar (72 PSI) approx

.

7.4 PRESSURE

GAUGE

Install a gauge as near as possible to the outlet of the Pump because the maximum pressure written

on the Pump’s Label refers to the pressure detected in that point and not on the nozzle or on other

accessories.

All the components of the machine or of the circuit must have technical specifications

compatible with the data written on the Pump’s Label.

8.

INSTALLATION, START UP AND SWITCHING OFF

8.1 POSITIONING

Smaller and lighter pumps can be handled by hand in compliance with current standards. Heavier

pumps must be handled using a suitable lifting device. If you need to use a lifting device, use

appropriate strap/s, being careful not to damage the product. The weight of the pumps is written in

the table on page 17.

To safeguard the lifetime of the components subject to wear and tear such as valves and

diaphragms, the pump should be installed below or at water level.

UDOR Diaphragm Pumps are, in any case, self-priming; they may be installed above the water

source. In this case, the maximum allowed difference in height is 2 mt. (6.5 ft.).

If the Pump is used in a particularly dirty workplaces or is exposed to atmospheric agents, you are

recommended to protect it, respecting the ventilation conditions.

8.2 ASSEMBLY

Fit the Pump on a rigid surface keeping the power take-off and support feet horizontal to ensure

correct drainage in the case of leakage of water or oil. The Pump must be secured firmly on a base,

which must be perfectly aligned with the transmission components. In the case of belt transmission,

make sure the pulleys are aligned and check the tension of the belts.

Use appropriately sized hoses, both on the inlet and outlet of the Pump, according to the technical

specifications written on the Label

.

8.3 START

UP

Before starting, check the following:

- Check the oil level through the dedicated oil reservoir or inspection cap; top-up if necessary.

- Check the pressure value on the accumulator, if installed; inflate or deflate if necessary.

- The pressure regulator valve must be set at “0” pressure to favour intake.

Start and run the Pump for approximately 10 seconds until all the liquid has discharged from the

delivery line. Once the intake cycle is complete, you can set the Pump at the required pressure, by

adjusting the pressure regulator valve, without ever exceeding the maximum pressure written on the

Pump’s Label.