IMP117-10

www.ueonline.com

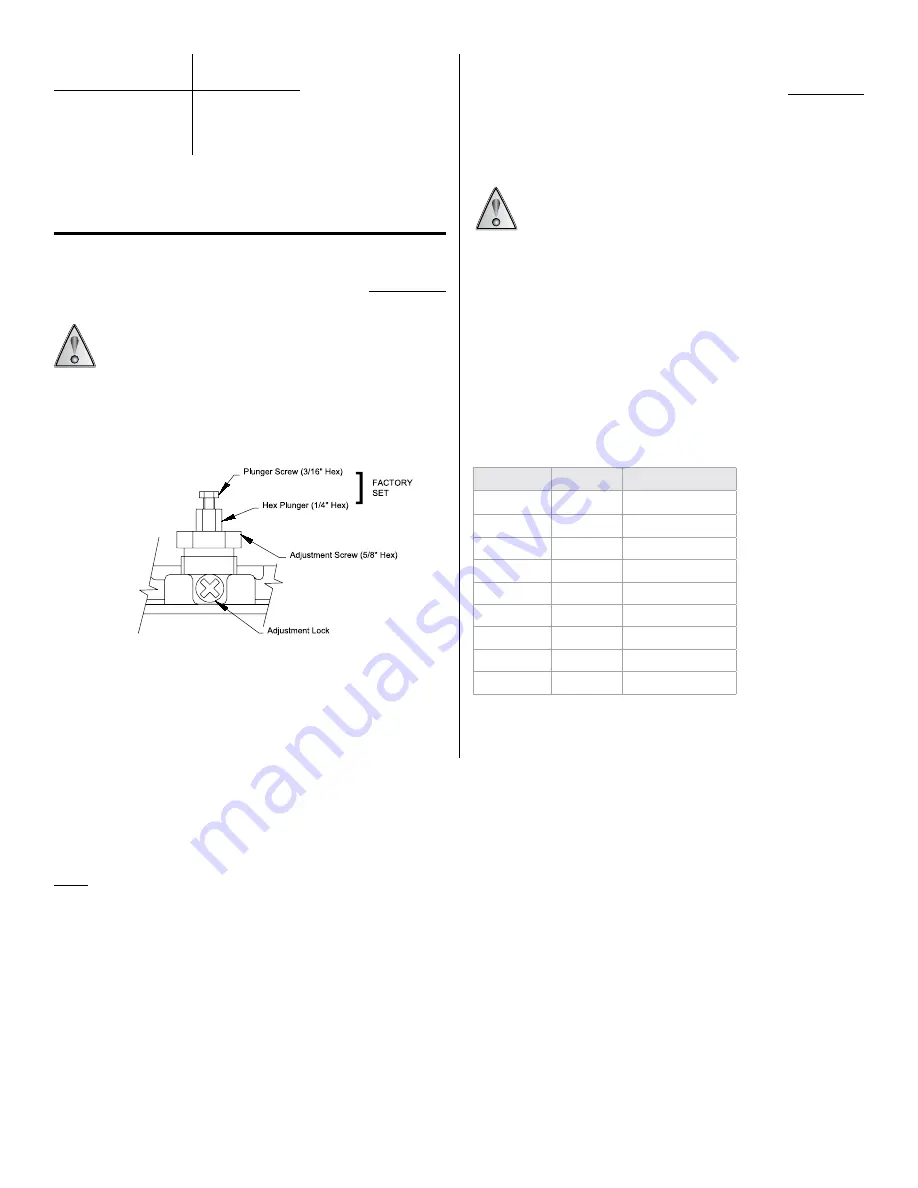

RE-GAPPING PRoCEDuRE (Refer to Figure 1)

Tools Needed

5/8” Open End Wrench

3/16” Open End Wrench

1/4” Open End Wrench

GAPPING IS FACTORY-SET AND CRITICAL TO THE FuNCTION OF THE

SWITCH. THIS PROCEDuRE SHOuLD ONLY BE PERFORMED IF THE

PLuNGER HAS ACCIDENTALLY BEEN ADjuSTED.

1. Loosen adjustment lock.

2. Turn 5/8” hex adjustment screw clockwise (left), to approximately mid

range. This puts a load on the sensor and exposes the plunger flats.

3. using a 1/4” wrench on the plunger and a 3/16” wrench on the plunger

hex screw, turn hex screw counter clockwise (right) from plunger until

switch actuates. If switch is already actuated, turn plunger hex screw

clockwise (left), until switch deactuates. Turn hex screw clockwise (left)

from this point. (see chart below for Flats and approximate Gap.)

4. Check set point according to Part II Adjustments.

5. Connect wires and replace cover securely.

Models

Flats

Approx. Gap

171-174

2-2 1/2

.0085 to .0105”

183-194

1-1 1/2

.004 to .006”

483-494

1-1 1/2

.004 to .006”

358-376

5-6

.020 to .025”

700-706

3 1/2 - 4

.014 to .017”

521-525

2-2 1/2

.0085 to .0105”

531-535

2-2 1/2

.0085 to .0105”

540-548

2-2 1/2

.0085 to .0105”

560-567

1-1 1/2

.004 to .006”

Part II - Adjustments

Tools Needed

5/8” Open End Wrench

ALL MODELS HAVE A TWO-PIECE ADjuSTABLE PLuNGER (SEE

FIGuRE 1). THIS FEATuRE IS CHARACTERIZED BY A 3/16” HEx

HEAD SCREW INSTALLED IN THE 1/4” HEx PLuNGER. THE LENGTH

OF THIS ASSEMBLY IS ADjuSTED AT OuR FACTORY AND IS CRITICAL

TO THE FuNCTION OF THE CONTROL DuRING NORMAL ADjuSTMENT, THESE

COMPONENTS SHOuLD NOT BE DISTuRBED.

†

Do not adjust unless re-gapping is necessary.

For set point adjustments and recalibration, connect control to a calibrated

pressure source.

Remove cover. Loosen Phillips screw adjustment lock. Adjust set point by

turning 5/8” hex adjustment screw clockwise (left) to raise set point, or

counter clockwise (right) to lower set point. Tension on adjustment screw can

be increased by tightening adjustment lock onto it. (See Figure 1). Controls

include uncalibrated reference scales for high, low or mid range settings.

When making adjustments, do not exceed the proof pressure* rating on

nameplate as this may cause a shift in set point.

NoTE:

Models 190-194 and 490-494 (welded stainless steel diaphragms).

These models are application sensitive. For rising pressure applications, set

point should be adjusted from low pressure up to set point. For falling pres-

sure applications set point should be adjusted from high pressure down to

set point. Wide pressure cycling above and below set point can cause control

band shift.

Adjustment Procedure for H117, H117K

Figure 1

†

SPDT

DPDT

Circuit 1 Circuit 2

Common

Violet

Violet

Yellow

Normally Closed Black

Black

Red

Normally Open Blue

Blue

Orange

Grounding screw and clamp (cast in symbol) are provided. Keep the wire as

short as possible to prevent interference with the plunger.