13

REPLACING THE BATTERIES

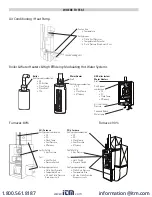

POST TEST

PERIODIC SERVICE

ANNUAL RE-CERTIFICATION

CLEANING

This meter has been designed for use with both alkaline and rechargeable Nickel Metal Hydride (NiMH) batteries . No other types are

recommended . The analyzer is supplied with 4 “AA” size alkaline batteries . These should be installed into the instrument as shown in the diagram

indicated on the back of the unit .

CAUTION!

Take great care when installing the batteries to observe correct polarity .

Always check the meter for operation immediately after installing

new batteries .

Using Re-Chargeable Batteries

The battery charger must only be used when NiMH batteries are fitted . Alkaline batteries are not re-chargeable . Attempting to recharge alkaline

batteries may result in damage to the product and may create a fire risk .

Battery Charging

Ensure that you use the correct charger . This unit uses a 9V DC regulated charger . Ensure that the batteries are fitted in the correct manner, and

then charge for at least 16 hours . Subsequent charges should be overnight . NiMH batteries may be charged at any time, even for short periods

to conduct testing .

WARNING!

Under NO circumstance should you expose batteries to extreme heat or fire as they may explode and cause injury . Always

dispose of old batteries promptly in a manner consistent with local disposal regulations .

WARNING!

Repair and service of this instrument is to be performed by qualified personnel only . Improper repair or service could result in

physical degradation of the instrument . This could alter the protection from personal injury this meter provides to the operator .

Perform only those maintenance tasks that you are qualified to do .

Remove the probe from the flue and allow the analyzer to purge

with fresh air until readings return to zero . - O2 to 20 .9%, CO to

Zero (Be careful as the probe tip will be HOT)

C85

L O N G L I F E E O S A N A L Y Z E R

CO

2

CO TEMP

Menu

Status

Aux

Eff

X-Air

O2

CO Air

Free

CO

2

CO

Temp

Fuel

Date

Time

O2% 20.9

COa -0>-

Drain water trap by unplugging

the drain plug and shake to

get excess water out .

Check particle filter for dirt

and any other sediment and

replace if necessary .

While the CO sensor has an expected life of more than five years in normal use it is recommended that the analyzer is re-certified at least annually .

This is so that long-term drift on the sensor and electronics can be eliminated . Local regulations may require more frequent re-calibration and

users should check with appropriate authorities to ensure they comply with relevant guidelines .

Periodically clean your instruments case using a damp cloth . DO NOT use abrasive, flammable liquids, cleaning solvents, or strong detergents as

they may damage the finish, impair safety, or effect the reliability of the structural components .

www.

.com

information@itm.com

1.800.561.8187