70

2. Check if the connection between the control box and the robotic arm,

power supply, and network cable is stable.

3. Check if the main power of the control box is on. If the ON/OFF light is

on it means power is on.

4. Check if the control box is turned on, if the status indicator of the

control box is on, it means the control box is turned on.

5. Check if the network is connected. If the network indicator in the

middle of the control box flashes frequently, it means the network

communication is normal.

6. Check if the robotic arm is powered and the emergency stop button is

disabled. If the power indicator of the robotic arm lights up, it means

the power is on.

1.2 Connect to the Robotic Arm

1.2.1 The Robotic Arm Network Settings

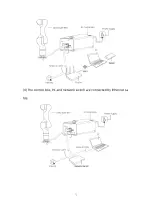

There are four ways of network settings for the robotic arm. You can

choose the appropriate network setting method according to your

scenario:

(1) The control box is directly connected to the PC.

Summary of Contents for 850

Page 1: ...1...

Page 72: ...72 4 The control box PC and network switch are connected by Ethernet ca ble...

Page 74: ...74 Step3 Open the Properties Step4 Open the IPV4...

Page 89: ...89 Cancel Cancel the selection Save Save the modified data Discard Discard the modified data...

Page 145: ...145 1 6 6 GPIO Control Box and End tool interface...

Page 149: ...149 1 6 7 End Effector...

Page 197: ...197 State 6 Stop Generally use studio will generate state 6 and state 6 is also a kind of stop...