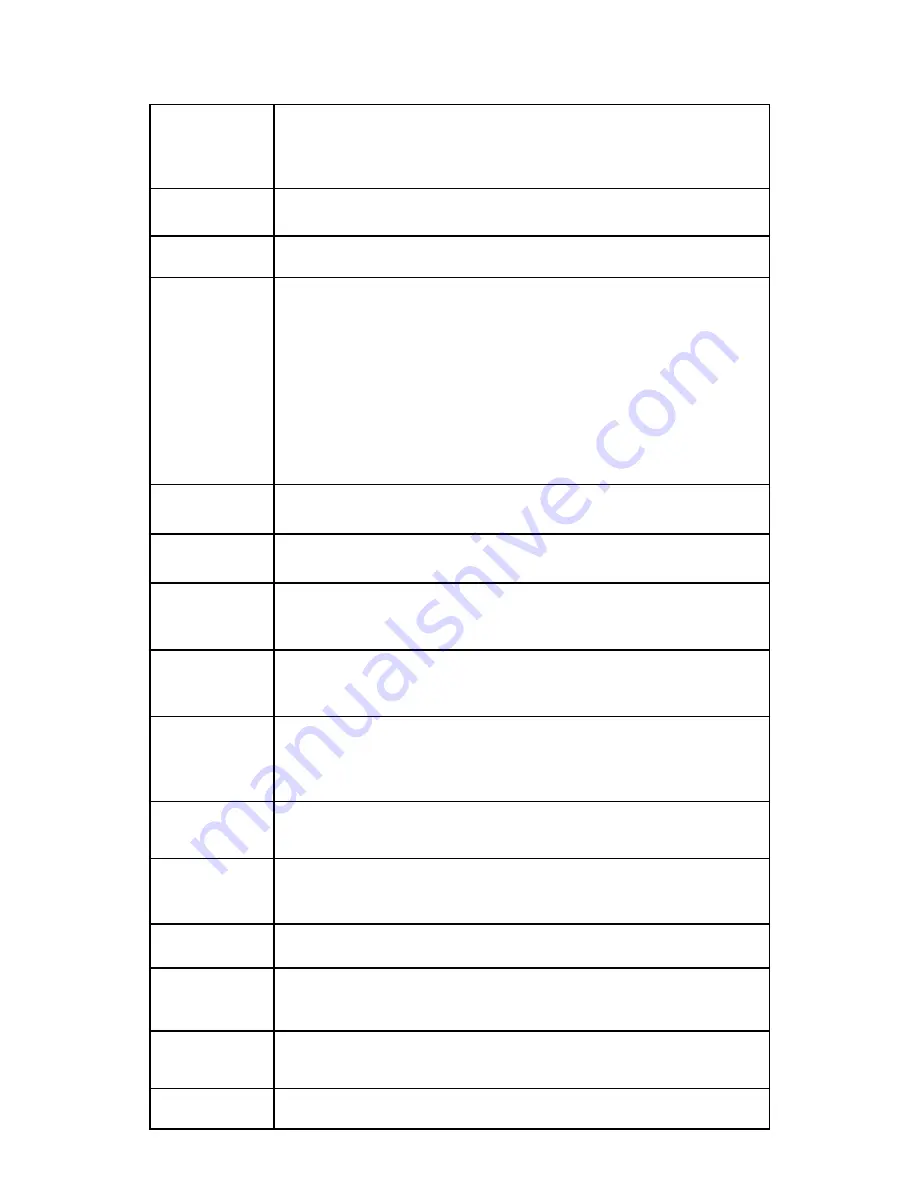

C27

Command Reply Error

Please retry, or restart the robot with the Emergency Stop Button on the

Control Box. If multiple reboots are not working, please contact

technical support.

C29

Other Errors

Please contact technical support.

C30

Feedback Speed Exceeds limit

Please contact technical support.

C31

Abnormal current in the robotic arm

1. Check whether the robotic arm collides.

2. Check whether the mass and center of mass set at "Settings"-"TCP

Settings"-"TCP Payload" match the actual payload.

3. Check whether the mounting direction set at "Settings"-"Mounting"

matches the actual situation.

4. Check whether the TCP payload parameters set in your program match the

actual payload.

5. Reduce the motion speed of the robotic arm.

6. Go to "Settings"-"Motion"-"Sensitivity Settings" to lower the

collision sensitivity.

C32

Three-point drawing circle calculation error, please reset the arc

command.

C33

Controller IO Error

If the error occurs repeatedly, please contact technical support.

C34

Recording Timeout

The track recording duration exceeds the maximum duration limit of 5

minutes. It is recommended to re-record.

C35

Safety Boundary Limit

The robot reaches the safety boundary. Please let the robot work within

the safety boundary.

C36

The number of delay commands exceeds the limit

1. Please check whether there are too many position detection or IO delay

commands.

2. Increase the tolerance of the position detection command.

C37

Abnormal movement in Manual Mode

Please check whether the TCP payload setting and mounting setting of the

robot are correct.

C38

Abnormal Joint Angle

Please stop the robot by pressing the Emergency Stop Button on the

Control Box and then contact technical support.

C39

Control Box Power Board Master and Slave IC Communication Error

Please contact technical support.

C50

Six-axis Force Torque Sensor Mode Setting Error

Please make sure that the robotic arm is not in Manual Mode, check

whether the given value of this command is 0/1/2

C51

Six-axis Force Torque Sensor Zero Setting Error

Please check the sensor communication wiring and whether the power is

normal.

C52

Six-axis Force Torque Sensor Overload

Please reduce the payload or applied external force.