138

【

】

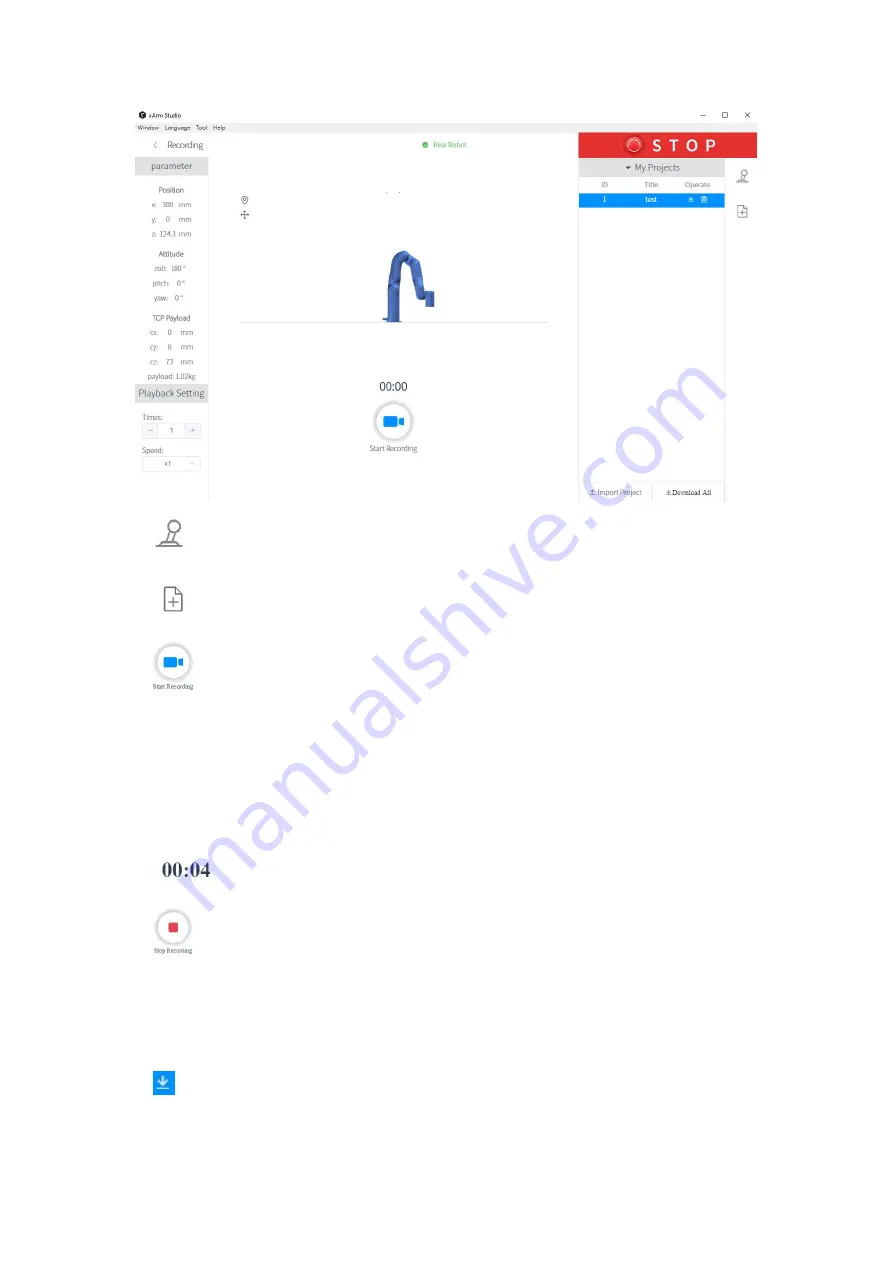

Pop-up live control panel.

【

】

Create a new recording file.

【

】

Manual Mode will be turned on accordingly by clicking on the button, and

the robotic arm can be dragged directly for trajectory recording. When

starting recording, be sure to pay attention to the load state of the robotic

arm, so as to avoid the big difference between the actual load and the set

load of the robotic arm, resulting in its self-motion.

【

】

Display recording time.

【

】

Stop recording.

【

Times

】

Set playback times.

【

Speed

】

Set playback speed.

【 】

Download the file.