2

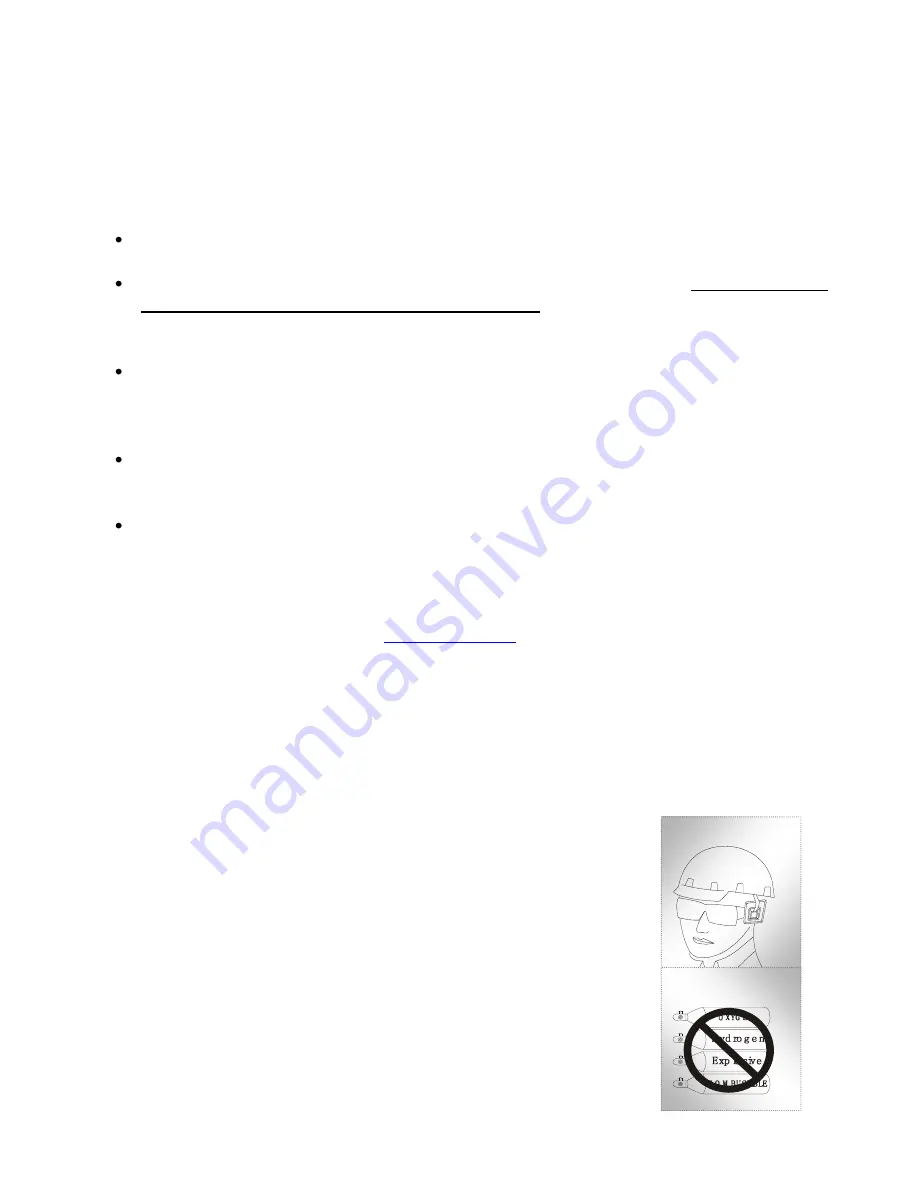

Fig 1.

Fig 2.

Description: Ballistic NailScrew Driver: Model NO. NSDCN65SP

is a heavy duty, coil fed, pneumatic

nailer, using compressed air as power source. It is designed to drive 15° plastic sheet coil or 15° wire coil

with full round head

Ballistic NailScrews®

or nails 1-

1/4” to 2.5” in length and 0.086˝ to 0.113˝ in diameter.

The NSDCN65SP was specialty designed for

UFO’s Ballistic NailScrew®

program with the ease of

installation and durability in mind. The power to easily drive color matched

Ballistic NailScrews®

into wood

or composites into light gauge (12 to 20ga) steel frame and stop the drive when it is flush. This is possible,

but must be done a little differently that what you may be used to when you are attaching wood to wood, so

please follow these step by step rules when installing into steel.

Consistent air pressure is the key to success. The closer to the compressor the better, but when long

runs of 3/8”air hose are necessary, the use of a surge tank will be necessary.

Keep the pressure high--110 to120psi; the high velocity this creates is our friend.

Please understand

this is where we are different than fastening to wood.

Always be sure to test fire into the actual

material scraps, adjusting the depth of drive on the tool

(See C Fig .19)

to compensate for the excess

pressure. Lower the pressure as a

last resort

and as little as necessary to get the job done.

The NSDCN65SP should be sequentially fired into steel. First, place the nose of the tool where you

want the fastener to be; this will depress the safety. Second, use the trigger to fire the tool in this

sequence each and every time. The tool must be placed squarely and very firmly; try not to let the

tool bounce off the work surface. This will give a more consistent drive and finished look.

When

you have a

Ballistic NailScrew®

that is too high or low, use a T15 Torx bit in a screw driver or

impact driver to adjust the NailScrew. Go very slowly to the desired depth. High rpm will strip out the

NailScrew. Go slow and you will be amazed at the results.

This is very important! Please make sure the frames are set very firm--not springy or bouncy. If the

frame moves much, it will cause the NailScrews to be set very inconsistently.

NSDCN65SP has very low noise level, making it ideal for installing

Ballistic NailScrews®

for Composite

fencing to wood or steel, construction of pallets and crate assembly, composite or wood deck construction,

roof decks, sub-floor, sidewall sheathing, anywhere screws are being used and you want to save time

installing and still do a quality job etc. (see

www.911.nails.com

)

IMPORTANT! Upon receipt of your NailScrew® Driver, Read and

follow all safety rules and operating instructions.

Important Safety Rules

1. KEEP CHILDREN AWAY.

All children should be kept away from the work area.

Do not allow them to handle the tool.

2. USE SAFETY GLASSES AND EAR PROTECTION.

Air tool operators and others

in the work area should always wear safety glasses to prevent injury from

fasteners and flying debris during use and when loading and unloading this tool.

Wear ear protection to safeguard against hearing loss. (See Fig 1.)

3. NEVER USE OXYGEN, COMBUSTIBLE FUELS OR ANY OTHER BOTTLED

GAS

as a power source as it will cause explosion and serious personal injury.

(See Fig 2.)

4. DO NOT CONNECT TOOL TO COMPRESSED AIR WITH PRESSURE

EXCEEDING 120PSI.

5. DO NOT USE AN EXCESSIVELY LONG AIR HOSE

in the working area as it will