5

9

This unit is not to be installed in areas subject to water-

spouts..

10

Do not use water-jets to clean the unit.

11

This unit can work in a room temperature range between

+5° and +32°C.

5 OPERATING PROCEDURES

1

Clean and sanitize the unit according to the instructions in

this manual. See chapter 5.3 CLEANING AND SANITIZING

PROCEDURES.

2

Fill the bowls with product to the maximum level mark. Do

not overfill.

The exact quantity of product (expressed as liters and gallons)

is shown by marks on the bowl.

3

In case of products to be diluted with water, potable water,

pour water into bowl first, then add correct quantity of product.

In case of natural squashes, it is advisable to strain them, in

order to prevent pulps from obstructing the faucet outlet.

4

Install the covers and check that they are correctly placed

over the bowls.

5

Set the control switches as shown in chapter

5.1 DESCRIPTION OF CONTROLS.

6

The dispenser must always run with the covers installed to

prevent a possible contamination of the product.

7

Always leave the dispenser on, as the refrigeration stops

automatically when the beverage reaches the dispensing tem-

perature. The mixing devices will continue to turn.

8

To maintain a high standard of flavour, keep refrigeration

and mixing devices on during the night when beverage is in the

bowl.

9

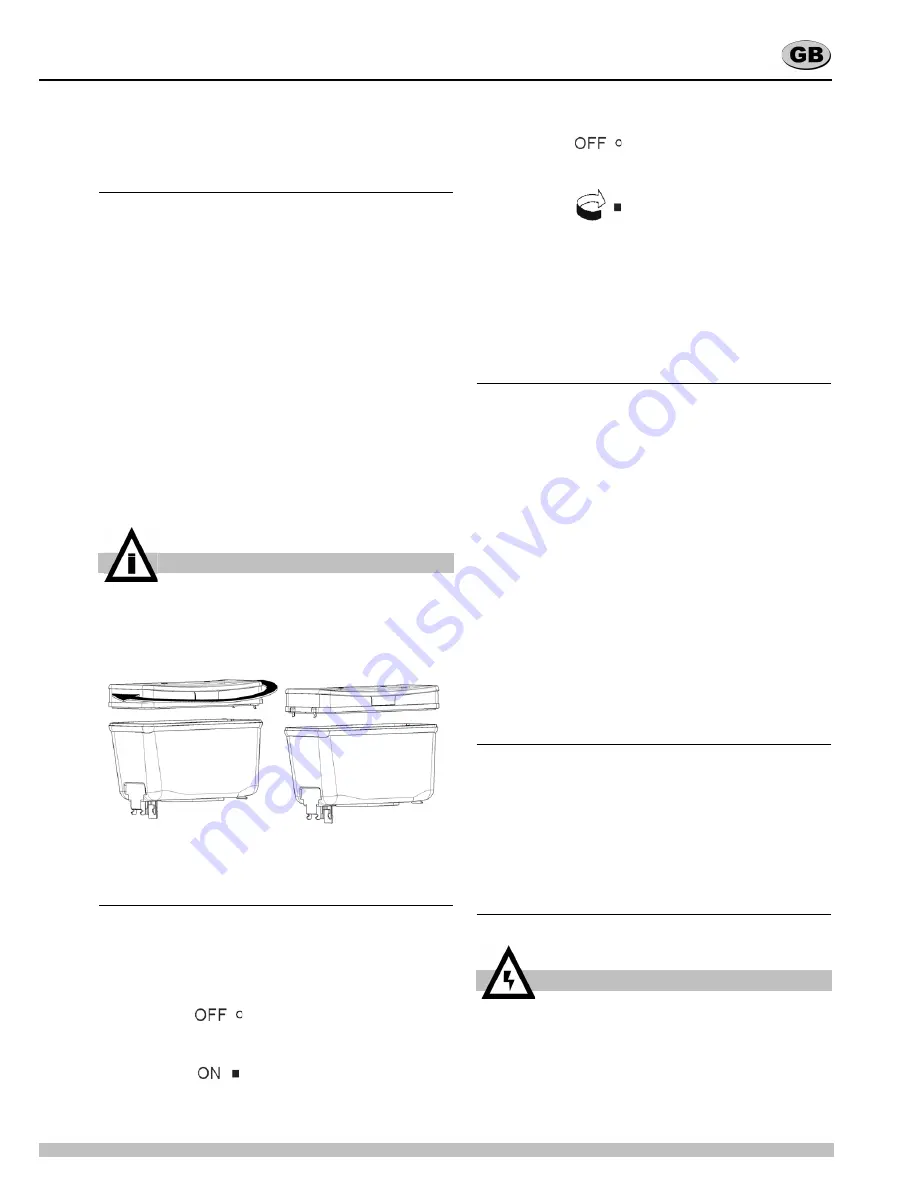

On machine equipped with lighted top cover turn the cover

for 180 degrees to switch light off. (see figure 1)

figure 1

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a power switch and each bowl is

operated by a mixing device switch.

Their functions are as follows:

Power switch

Mixing device switch

To operate the dispenser

1

Set power switch to I position.

2

Set mixing device switch(es) to I position.

5. 2 OPERATION HELPFUL HINTS

1

The length of time for cooling down the product is governed

by many variables, such as ambient temperature and beverage

initial temperature.

2

To shorten product cooling down time and increase pro-

ductivity, it is advisable to pre-chill the product to be used in the

dispenser.

3

To shorten product cooling down time and increase pro-

ductivity, the bowl should be refilled after the product level

drops lower than half and at the start of each day.

4

The dispenser must be able to emit heat.

In case it seems excessive, check that no heating source is

close to the unit and air flow through the slotted panels is not

obstructed by wall or boxes. Allow at least 15 cm (6”) of free

clearance all around the dispenser.

In any case if the product in the bowls is cold the unit is running

properly.

5

How to reset beverage temperature:to reset beverage tem-

perature please apply to a technician.

The proper temperature is preset at the factory.

5. 3 CLEANING AND SANITIZING

PROCEDURES

Cleaning and sanitizing of the dispenser are recommended to

guarantee the conservation of the best product taste and the

highest unit efficiency. This section is a procedural guideline

only and is subject to the requirements of the local Health

Authorities.

Prior to the disassembly and cleaning, the machine must be

emptied of product.

5. 3. 1 DISASSEMBLY

1

Remove cover from the bowl.

2

Remove the empty bowl by lifting pulling lever (1) and its

IMPORTANT

Operate the dispenser with food products only.

0 position

: Power is turned OFF to all

functions.

I position

:

This position operates the fan

motor and makes the mixing

devices suitable to be turned

on by relevant switches.

0 position

: OFF.

I position

: Mixing device runs.

ATTENTION

Before any disassembly and/or cleaning procedure make

sure that the dispenser is disconnected from its power

source by unplugging it or switching off the 2-pole wall

breaker.