Service manual

Compact electronic knob cylinder

9

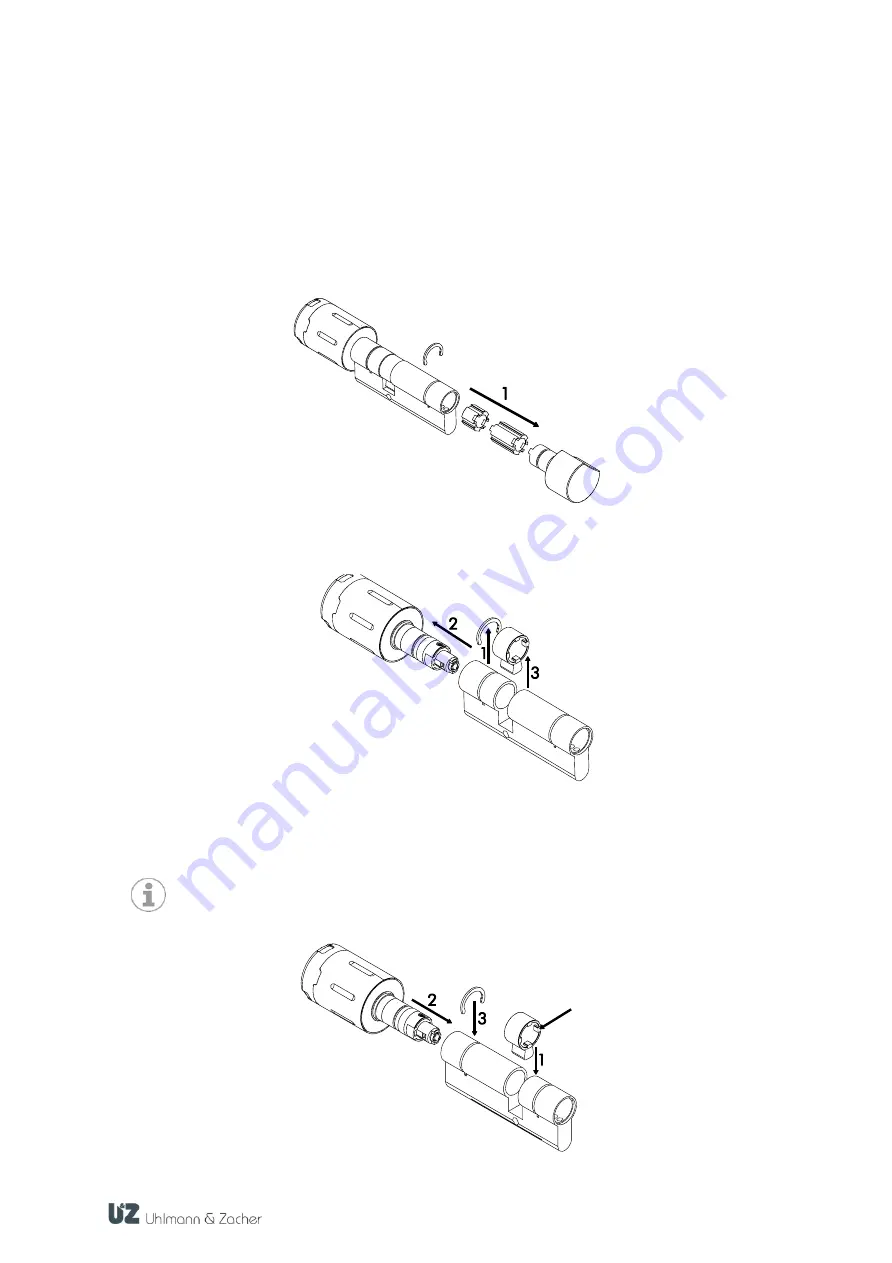

Remove the parts out of the cylinder carefully. Do not change the position and sequence. Different parts

are used depending on the cylinder dimensions.

Remove the snap ring from the electronic knob, pull it carefully out of the cylinder and remove the lock-

ing cam.

Rotate the cylinder and hold the locking cam in the cylinder opening, such that the four inner tappets

point towards the mechanical knob. Then insert the electronic knob into the appropriate side of the lock-

ing cylinder and secure it with the snap ring.

From a cylinder dimension of 45/xx onwards, the locking cam can be inserted in the cylinder

opening even after mounting the electronic knob.