13

With the burner comes a temperature giver

controlling start and stop of the burner. This giver

should be placed in one of the plunger pipe of the

boiler or in suitable place under the isolation of the

boiler so high up as possible since the water

temperature is warmest there.

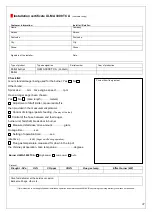

In this menu you read the present boiler temperature

and set the desired hysteresis.

The basic setting is that the burner starts at 65

degrees and turns off at 85 degrees. At longer

operation times the effect increases and gives a

better efficiency. Shorter intervals give more starts

per 24h and contribute to more wear on ignition

element and give higher fuel consumption. Therefore

we recommend a hysteresis of minimum10degrees

difference.

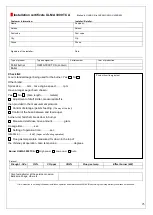

The control system also keeps track of some history

that could me useful to the installer at service. This

history shows how many ignition errors, fuel errors

and if any overheating have occurred via the sensing

giver that is placed on the tipping chute and has the

function of cutting the power to the burner if it is

starting to get too hot up in the tipping chute. This

giver is part of the security.

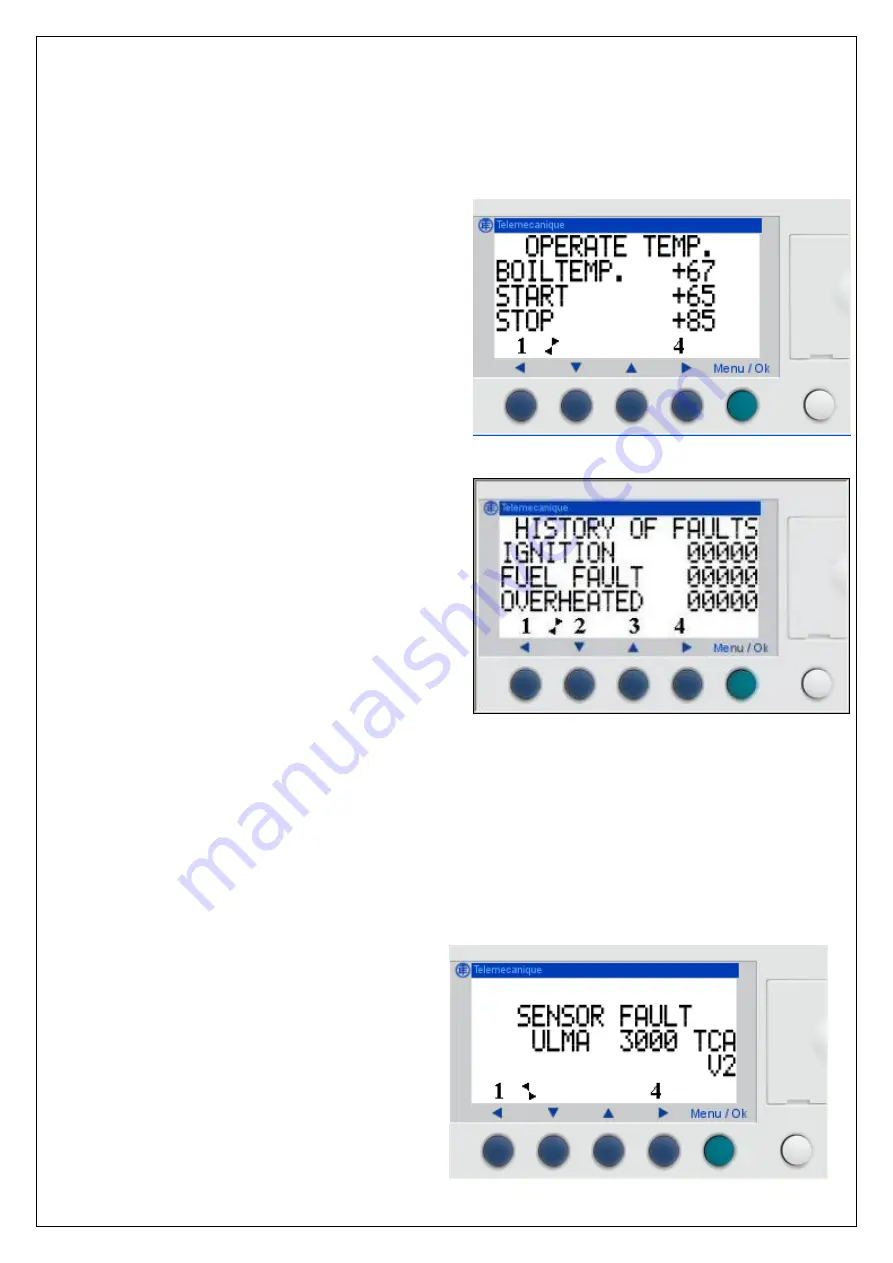

Alarm

(The display shows a message and the burner has turned off)

At this alarm something has happened to the

giver that controls the boiler temperature. Do not

do any attempts to start the burner, we

recommend that you turn off the switch on the

burner. Immediately contact your nearest

retailer/installer or ULMA AB.