19

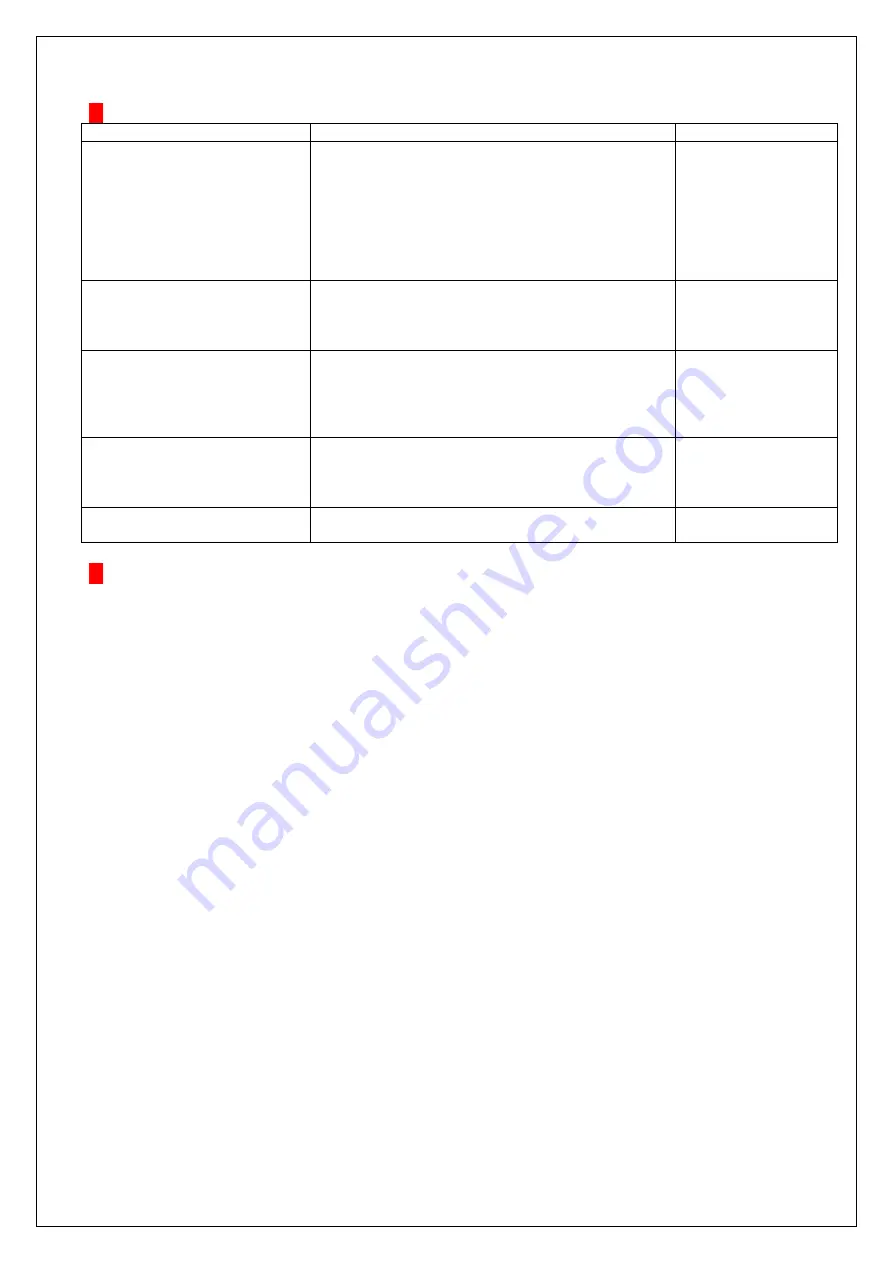

Fault diagnosis schedule

Fault

Cause

Action

The burner has stopped.

Fuel fault

on display.

1. The pellet storage is empty.

2. Air pocket has been created in the inlet of the

feed auger.

3. The auger has been blocked by waste.

4. Stop in tipping chute.

1. Fill with pellets.

2. Shake the storage

so that pellets fall

down.

3. Knock hard on the

conveyor.

4. Too big start dose.

Decrease start dose.

The burner stops even though it

ignites.

1. Too heavy feeding at operation level.

2. Flame guard dirty or broken.

1. Adjustment of fuel

amount.

2. Clean or change

flame guard.

The burner does not ignite.

Ignition fault on the display.

1. Wrong start dose.

2. Broken ignition element.

3. Stop in tipping chute.

1. Change start dose.

2. Change ignition

element.

3. Clean tipping

chute.

The burner stops now and then

without visible reason.

1. Incorrectly adjusted burner.

2. Too big or heavy under pressure in the chimney.

3. Error in the fuel feeding.

1. Adjust the burner.

2. Mount draft limiter.

3. Clean feed auger

from chips.

Overheating on display.

Too bad draft in the boiler.

Sweep the boiler.

Data

and Service information

Safety regulations

The product is CE-marked which means that it fulfills all prescribed requirements that exist to put the product

into work within the EU. ULMA AB disclaims all responsibility that could occur at misuse or wrong use of the

Ulma3000TCA burner.

Change of ignition element

1. Loosen all 3 cables to the burner.

2. Demount the burner cover by loosing the 4 screws and then carefully pull the cover backwards.

3. Loosen the quick-action hooks that hold the outer pipe towards the back cover. Carefully separate the

burner.

4. Loosen the screw that holds the ignition element and pull out the element from its position.

5. Re-mount in reverse order.

Change of flame guard

1. Loosen all 3 cables to the burner.

2. Demount the burner cover by loosening the 4 screws and then carefully pull the cover backwards.

3. Loosen the connection cables on the control system and pull out the giver from its hole to the left of the

fan.

4. Push in the new giver in the holder 25 mm and fasten the nut. Connect the connections to the control

system and remount the burner cover in reverse way.