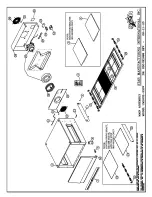

1,2: AC IN

3: FG

4,5: -V OUT

6,7: +V OUT

PS

GM/C

C1

DSIC

PS

M1

OCB

TS1

TL2

TL1

CB

SE

FS

DS

S1

XF1

CON

TB

CB

- GEARMOTOR & CONTROLLER

- CAPACITOR, CIRC FAN MOTOR

- DIRECT SPARK IGNITION CONTROLLER

- POWER SUPPLY, 24VDC 150W PS

- MOTOR, CIRC FAN

- OVEN CONTROL BOARD

- COOL DOWN T-STAT

- CONTROL BOX TEMP LIMIT (MAN RESET)

- COOK CHAMBER TEMP LIMIT (BULB & CAP)

- CIRCUIT BREAKER

- SPARK ELECTRODE

- FLAME SENSOR

- DIFFERENTIAL PRESSURE SWITCH

- SWITCH, MAIN

- TRANSFORMER, 230V-24V

- CONTACTOR

- TERMINAL BLOCKS (2)

- CONNECTION BLOCK

36

13

20

41

1

2

3

4

5

6

7

BLK

BRN

BLU

M1

C1

TL2

TS1

32

TB

5

4

_

8

9

36

10

_

19

21

41

21

_

_

_

30

18

BLU

15

9

SET VOLTAGE TO 230V

BEFORE INSTALLING

17

BLK

BRN

T/C

10

PR

17

"L" "H"

DS

C

NC

NO

NOTES:

FOR FIELD WIRING BY INSTALLER WITH CORD OR FLEXIBLE

CONDUIT. (2) EXTRA J1 JUMPERS FOR SINGLE PHASE USE

(TIE L1,L2,L3 TOGETHER) WRAP THESE WITH OTHER LOOSE

SHIP PARTS

4

C

3

MOTOR

COM

ENABLE

DIR

SPEED

COM

TACH

5 TO

ALL MOTOR

SPEED (GRD)

SPEED SIGNAL

SPEED (5V REF)

(NOT USED)

TACH (GND)

TACH (+5V)

TACH SIGNAL

CB

COND GENERATION

CN1 T/C TYPR K

YEL(+) RED(-)

SH (SHIELD)

CN1

CN2 (24V)

INPUT

2 = N

1 = H

CN4

_

1

23

34

CN2

1

33

25

CN4

OUTPUT TO

SOLENOID

3 = COM

2 = 24V

1 = N/C

R

RDL

A

0

9/15/03

B

0

3/26/04

RDL

C

9

/23/04

CG

MA

TERIAL

DR.

FINISH

MODEL

NO.

TITLE

P

ART NO.

ST

AR MFG. INTERNA

T

IONAL, INC.

#10 SUNNEN DRIVE, ST

. LOUIS, MO. 63143, USA

T

O

LERANCES UNLESS OTHER

WISE NOTED

DESCRIPTION OF CHANGE

FRACTIONS ±1/64 DECIMALS ±.005 ANGLES ±1°

THIS DRA

W

ING CONT

AINS INFORMA

T

ION CONFIDENTIAL

T

O

ST

AR MFG. INT'L

INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

DR

REVISIONS

CK.

---

---

UM-1833

SK-1987

WIRING DIAGRAM, 400/230

RDL

04/30/03

LT

R

D

AT

E

DA

TE

BL

ADD 2ND GENERA

T

ION CONTROLLER

SHOW BEND IN T/C FOR NEW MOUNT

UPDA

T

ED OVEN CONTROL

BOARD

TL1