Version 1.05 March 2020

24

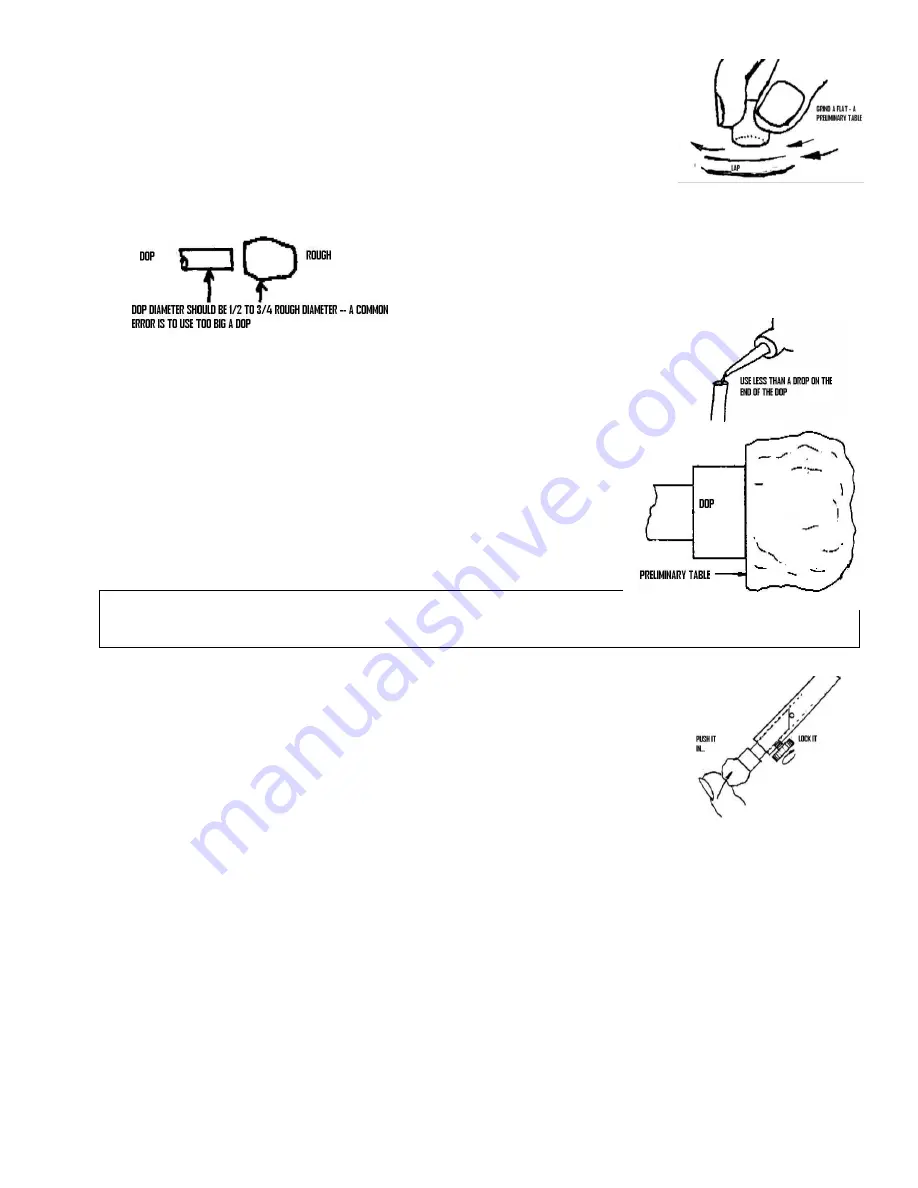

6.2.2 THE FIRST CUT

– A PRELIMINARY TABLE

Having determined where the table should be, hold the stone in your fingers and

using a 360 grit lap

(or a 600 Lap if that’s coarse enough to remove the material

you want to remove), grind a "preliminary" table--you need a surface large enough

for attaching the dop. This surface will provide you with a reliable reference surface

for the cutting of the stone.

6.2.3 DOPPING THE STONE

The stone is cemented to a dop--the process is called "dopping". Select a flat dop which ranges between 1/2

and 3/4 of the projected diameter of the stone. Clean both the

stone and the end of the dop in denatured alcohol (obtainable

at your hardware store). Wipe these items dry with a lint-free

paper towel. Place just enough adhesive on the end of the dop

to coat the surface (*see the note below). Bring the preliminary

table in contact with the end of the

dop. The adhesive we recommend

gives you about 30 seconds to position the stone--that is plenty of time and you will

find you can position the dop by eye surprisingly well. In your first attempt you may

use more adhesive than needed; you need less than a drop. Too much will cause the

setting up process to take a longer--if you have applied too much, you can wick it off

onto a bit of paper.

Hold the stone and dop together under finger pressure for approximately 30

seconds. Run a very light bead of adhesive around the stone and set it aside

for at least five minutes to assure a good bond. Not very difficult. (Do be

sure to observe the caution notes on the bottle--this type of adhesive bonds

skin very effectively). After the waiting time, tug a bit on the stone to satisfy

yourself it has adhered well.

We recommend is

a “super glue”, specifically Loctite 404, available from

Industrial suppliers. It is expensive compared to others, but we found it more reliable, and still only a few

pennies per dopping. If you don't have an Industrial supplier nearby, you can get Loctite 404 from us.

Insert the Dop into the Spindle, so that the chamfer on the dop engages the

alignment pin in the Spindle--push it in snugly. Tighten the Dop-retention Set screw

(it tightens with a normal CW action).