EDGE 540

請注意

.組裝前請先閱讀使用說明書

.初學無任何組裝經驗者請與經驗較豐富的高階玩家一同組裝

.請在孩童拿不到零件的環境下組裝以確保安全

.請保留本說明書方便您日後的快速查閱

PRECAUTION

.

Please read through the entire instruction manual before you start .

.

First time builders if not familiar with the processes in the manual,

please find an experienced builder to help with assembly.

.

Always keep children away from the assembly area due to small parts

and glue which are dangerous to children.

.

Please save this instruction manual for future repair or parts ordering

purposes.

-------INDEX

●

Parts index

.零件表__________________________________________

01

●

Tools and radio required to assembly

.組裝前注意事項__________

02

●

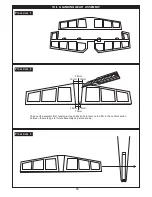

2.Main Wing assembly

.主翼的組裝____________________________

03

●

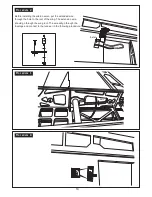

3.

Tail & Landing gear assembly

.尾翼組與輪架組裝_____________

05

●

4.

Power system & cowling assembly

.動力組與整流罩組裝 ______

11

●

5.Servo assembly

.伺服器的組裝_______________________________

13

●

6.CG & Control Adjustment

.重心及設定的組裝________________

18

www.ultraflymodel.com

For Advance Flyers

.適合進階玩家

EDGE 540

Length (

全長

)

1190 mm

43.3 In

Wing Span (

翼展

)

1100 mm

47.2 In

Wing Area (

翼面積

)

27.7 Dm

2

429.4 sq.In

All up Weight(

全備重

)

1200 g

42.34 oz

Wing Loading (

翼荷重

)

46.21 g/dm

2

15.1 oz/sq.ft

Radio Requirement

4 Channel

4(

動作

)

Summary of Contents for Edge 540

Page 21: ......