5. The most common setup process for welding applications:

1. Connect the transducer (tran amp mould combination) through the 2-core aviation

plug on the back of the device.

2. Connect the equipment to 220VAC power and turn on the power.

3. On the touch screen interface, click the "Frequency Search" button to enter the frequency search

interface, and press the "Start" button to search the resonance frequency of the welding head.

4. After successful search, it will automatically exit to the main interface. If an error is reported,

please check the possible cause according to the instruction manual.

5. Set the amplitude to 40%. According to the sonic test, observe whether the current is within 1A,

whether the power is within 500W, and whether the sound is mainly based on crisp model

frequency sounds. If you report an error that is out of range, you should check the mold or

transducer for abnormalities, and the mold is not tightened, cracked, etc.

6. Short the pins 1 and 6 of the DB9 interface on the back of the device through a control device

such as a button or PLC. Start ultrasound

7. Adjust the amplitude according to the welding result to meet the welding requirements. Note that

after adjusting the amplitude, the sound wave needs to be restarted to take effect.

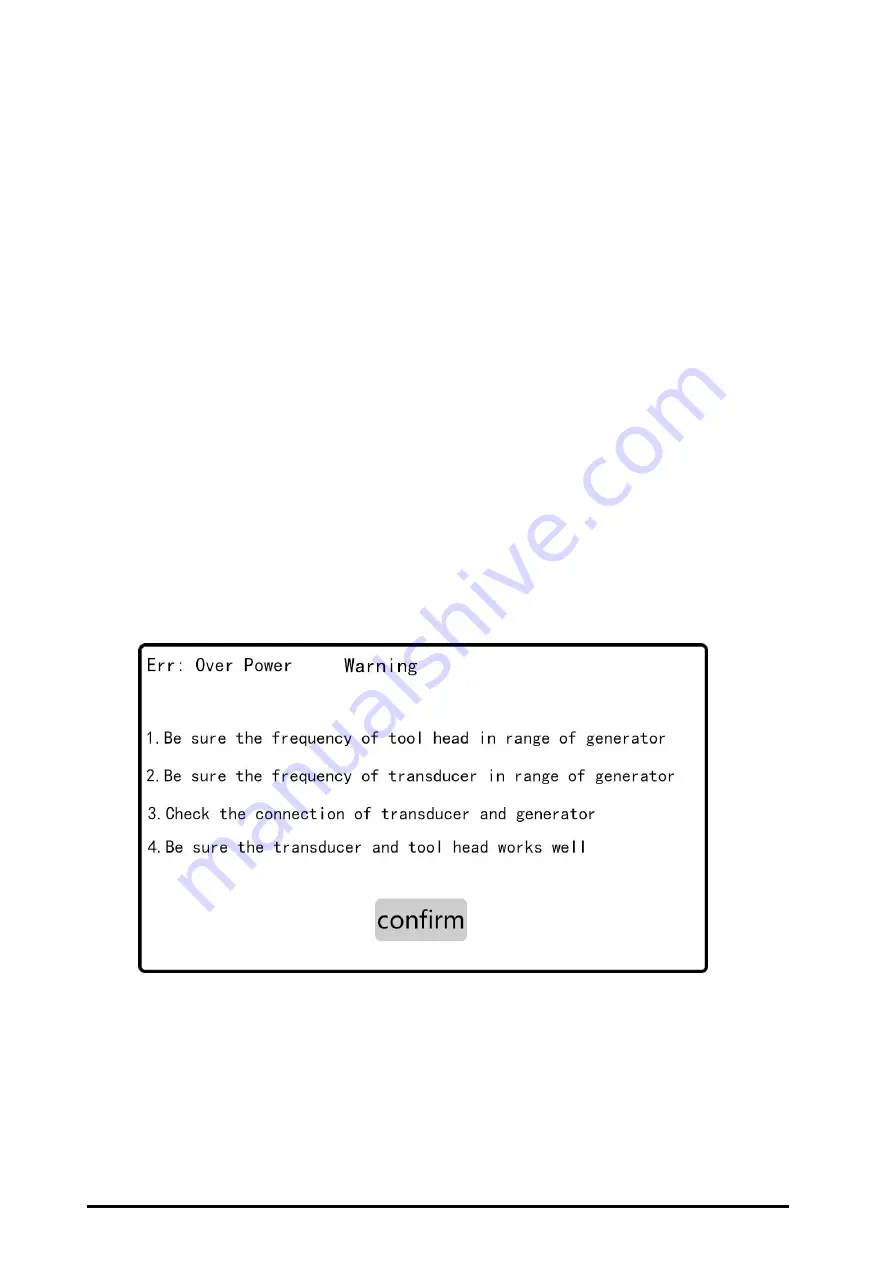

6. Warning messages and possible causes

6.1 Error: Lock frequency is out of DAC coarse adjustment range

Triggering this protection indicates that the frequency has lost lock, and the microcontroller

frequency is adjusted to its own capacity limit or the correct operating frequency has not been

found.

When this error occurs, try: