28

Property of Ultrasonic Power Corporation - © 2019

Publication # 190610

14.

H

EAT

C

ONFIGURATION

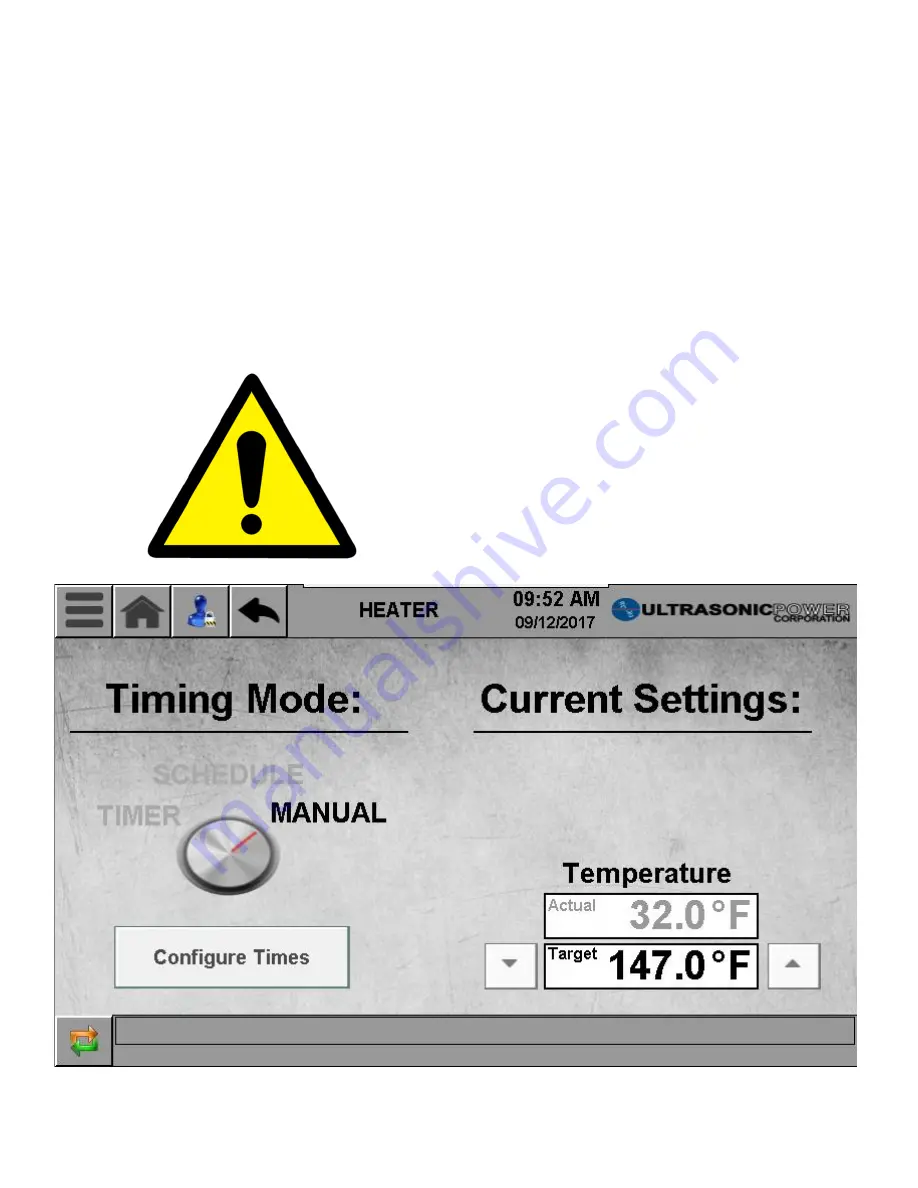

The heat configuration page allows the user to determine the means by which this

peripheral will operate. Modes include:

1) Manual- allows the user to operate the peripheral directly from the home screen.

2) Timer (Countdown)- allows the peripheral to operate for a predetermined amount of

time. (9:59:59 maximum)

3) Schedule (7 Day Timer)- allows the peripheral to operate via a 7 day timer

programmed by the user.

Caution

-

Ensure tank contains the

minumum required amount of liquid prior

to operation.

Warning

-

Ensure proper drainage or liquid

removal is installed prior to operation.