Troubleshooting

A-2

ULVAC CRYOGENICS INCORPORATED

Ⅲ

Compressor

stops after

operating

several minutes

1) Thermal protective switch (TS3)

is ON.

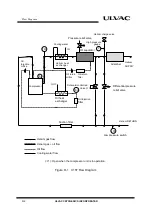

Check that the cooling water is

flowing and its flow rate. (See

Fig.3-2)

2) Low pressure switch (LPS) is ON. Add helium gas till the static

pressure.

3) Circuit protectors (CP1, CP2) or

thermal relay (OL) are active.

Check the power supply voltage.

Contact our Service Engineering

Division or the nearest CS center.

(The cooling water temperature

and the room temperature will be

needed.)

4) Thermal protective switches (TS1

and TS2) are active.

Contact our Service Engineering

Division or the nearest CS center.

5) Compressor failure.

Contact our Service Engineering

Division or the nearest CS center.

Ⅳ

Compressor

makes

abnormal noise

during

operation.

Helium charge pressure is too high.

Check helium charge pressure.

The pressure must not exceed

1.65MPaG (at room temperature

of 20

℃

).

Summary of Contents for C15T

Page 2: ......

Page 8: ...F 6 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 14: ...S 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 16: ...IW 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 34: ...Operation 4 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 38: ...Disconnection and Storage 5 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 46: ...Maintenance 6 8 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 50: ...Troubleshooting A 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 54: ...Circuit Diagram B 4 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 57: ...Flexible Hose C 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 61: ...CS 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...

Page 63: ...Revisions R 2 ULVAC CRYOGENICS INCORPORATED This page intentionally left blank...