-

10

-

(5) After verifying that the power switch of the pump is turned OFF, connect the

power cord or the motor lead to the power supply according to the motor rating.

(6) Turn ON the pump to check that pump is pumping.

(7) After that, turn OFF the power to stop the pump.

(8) Install either a circuit protector or a glass pipe fuse.

(9) Make piping arrangement ensuring that no leakage occurs in the suction pipe.

Use as short a hose as possible. If a long hose is used, it will take longer to pump.

(10) When attaching the pipe to the exhaust or suction opening, tighten the pipe to a

torque of 6 N

・

m. Too much tightening force could damage the exhaust or suction

opening.

(11) Make piping arrangement so that the exhaust port tree tram is a backing pressure.

(12) In case of selecting the inlet pipe and exhaust pipe that are not from our products,

please select the exhaust pipe that has same or larger inner diameter length with

the inlet pipe.

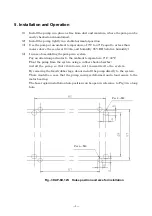

(13) Typical vacuum pumping diagram is as shown in Fig-4. (Timing valve )Pump vent

valve to start easily the pump is attached close by the pump. Also, isolation valve

to keep the chamber in vacuum is equipped between the pump and the chamber.

(When pump is operating: Isolation valve is open, timing valve is closed)

(When the pump is at a stop: Isolation valve is closed, timing valve is open)

Fig.-4 Vacuum pumping diagram

VACUUM

PUMP

FILTER

PUMP VENT VALVE

(TIMING VALVE)

ISOLATION VALVE

CHAMBER