-

14

-

Tools Required for Setup

Have the following tools on hand and perform the replacement while referring to the diagram.

If there is no repair technician available

, or if you do not have access to the required tools,

please make the appropriate request to our repair services department.

・

Required Tools

1.

Phillips head (+) screwdriver- No.2

2.

Torque screwdriver- No.2 (0.25-0.30 Nm, 1.2 Nm, 4.0 Nm)

3.

Tri-wing bit (special tool)

* This bit is to be used with the torque screwdriver (0.25-0.30 Nm).

Please see the pictures below. Use this to fasten/loosen the tri-wing screws.

4.

Anti-loosening agent for screws

Replacing diaphragm : Loctite 242 or Loctite 243

Replacing

valve

:

Loctite 262 or Loctite 263

5.

Rag

6.

Solvent for wiping (something that has no effect on rubber, such as ethanol)

7.

Dust mask (for nose and mouth), gloves, protective eyewear

*Use items No.5 and 6 to wipe down any dirty area when replacing the part.

Part Replacement Procedure

Definition of Terms

In the replacement procedure, the terms

“

primary side

”

and

“

secondary side

”

shall be used to refer

to specific locations.

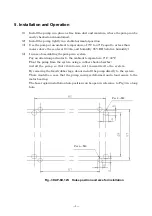

Refer to the terms and diagram below when performing the replacement.

Tri-wing bit

Tri-wing screw

DAP-6D

DAP-12S

Secondary side

Primary side

Primary side

Secondary side

Suction

inlet

Exhaust

outlet

Exhaust

outlet

Suction

inlet

Rc 1/8 tap

Rc 1/8

tap

Rc 1/8 tap

Rc 1/8 tap