-22-

4.2.2 Start-up and shut-down

①

Start vacuum pump according to 4.1.1 Operation [page 20].

②

Stop vacuum pump according to 4.1.2 Shut-down[page 20].

Important

Continuous evacuating of humid gas

When evacuating vacuum chamber while humidity in chamber is high, moisture volume drawn into pump

differs

according to temperature and pressure in chamber.

When pumping vacuum chamber containing humid gas, be sure to open air-flush port and operate pump (air-flush

opened operation).

Be careful not to damage air-flush port (especially air-muffler section).

Damage to air-flush port can cause failure.

When doing air-flush opened operation

Noise level will increase (by 3dB).

Install pump in an area which is not exposed to debris such as iron powder, stone powder,

polish powder or wood dust.

Debris can clog air-muffler, undercutting air-flush effect.

Be sure to close isolation valve between vacuum pump and vacuum chamber during pump

shut-down.

If vacuum pump stops during air-flush opened operation, atmospheric air is drawn back from air-flush port to inside

of vacuum pump, and vacuum on chamber side cannot be maintained. Be sure to close isolation valve between

vacuum pump and vacuum chamber to prevent the drawback of debris from vacuum pump into vacuum chamber

before stopping vacuum pump.

When operating with air-flush OFF (closed), operate as per 4.2.3[page 22].

4.2.3 When returning to air-flush closed operation

Before starting air-flush opened operation, first stop vacuum pump and proceed in

accordance with the following procedure. Never perform this procedure during

operation.

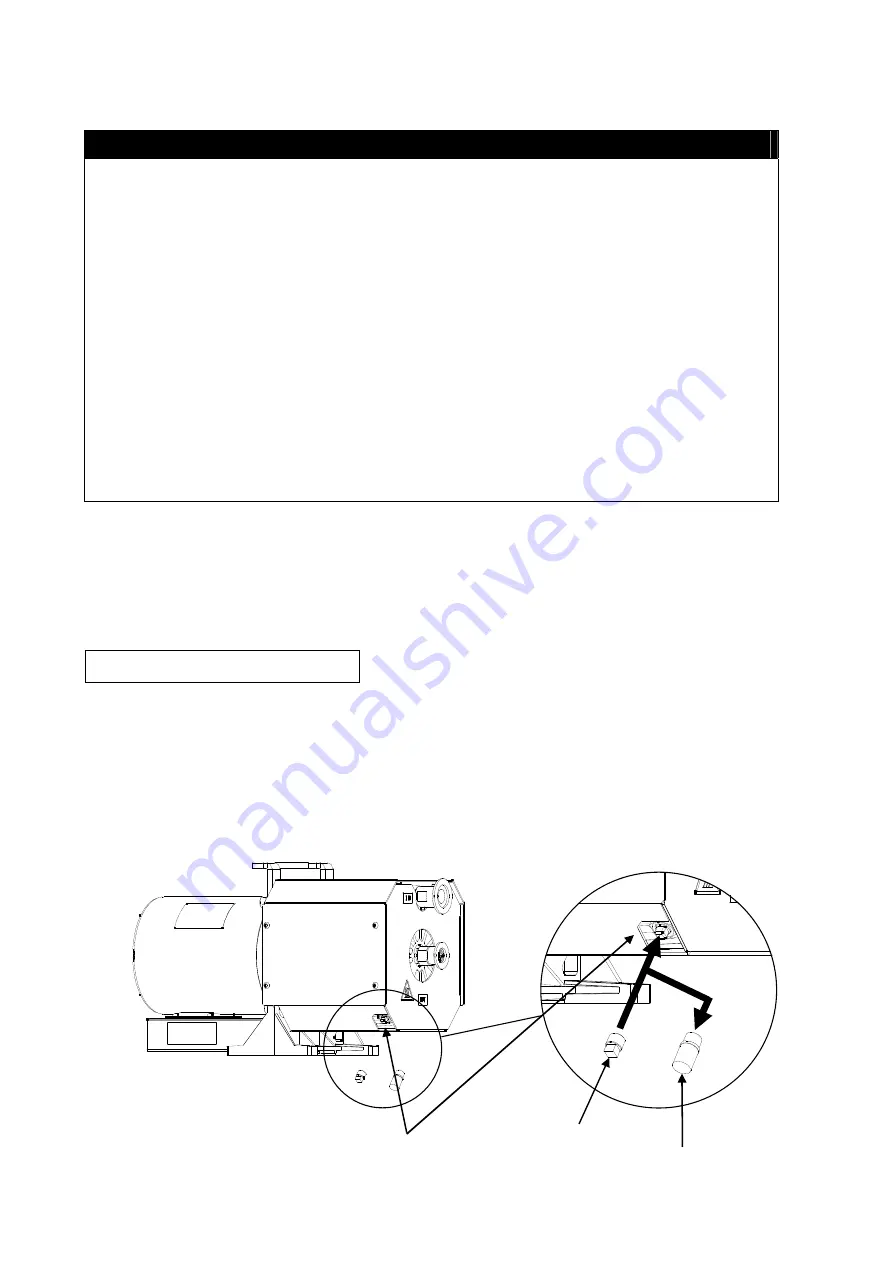

Remove air-muffler

①

Stop vacuum pump.

②

Remove air-muffler from air-flush port.

③

Lightly fit plug to air-flush port with a spanner (nominal dia. 7mm).

※

When restarting air-flush opened operation, refer to 4.2.1~4.2.2[page 21~22] and

prepare and start.

※

Store removed air-muffler and pay attention not to misplace it.

Remove air-muffler

Fit plug

Air-flush port