SECTION 3

6

3. MOUNTING THE ELECTRON BEAM GUN

3.1 Necessary Equipment

(1)

Power supply unit for electron beam gun

ULVAC HPS series electron beam gun power supply unit, such as

HPS-1000F, HPS-1600F, etc.

(2)

Pumping unit for deposition

1 set

(3)

Gun base (SUS 304) for the above

1 set

(4)

High voltage feed-through

2P (dual)

(50 A, 12,000 VDC or more)

* ULCAV BERH-311A (100 A, 12,000 VDC, 1P) is recommended.

(5)

Feed-through for magnet coil

(Current capacity: 5 A, breakdown voltage: 250 VAC or more)

* ULVAC recommends the use of PTS-004 (8P).

(6)

Ground terminal

Fix an M10 bolt to the electron beam gun chamber wall and connect it to the

gun by means of a copper strip.

Outside the chamber, the bolt is connected to the earth cable and ground cable

of the E/B power supply.

* ULVAC recommends the use of ERZ-003.

(7)

Grounding (10 or less)

* See the Electron Beam Gun Power Supply instruction manual.

(8)

Flow switch

* ULVAC Model GTF-A (2 to 20 L/min) can be used.

(9)

Chamber close switch

125 VAC, 0.5 A

(10)

Vacuum interlock switch

125 VAC, 0.5 A

ULVAC Model DTA-001 can be used. Interlocking can be done more

effectively by using the meter relay of the ionization gauge.

(11)

Water feed-through

Inside diameter: 8mm-dia. or more

2P/gun

(12)

Evaporation source shutter mechanism

1 set

(13)

Hearth rotation mechanism

1 set

Two-thirds turn of the hearth drive shaft of the EGL-206M/EGL-406M

moves one crucible.

Summary of Contents for EGL-206M

Page 2: ...EB0007 03e...

Page 3: ...EB0007 03e...

Page 10: ......

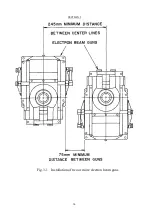

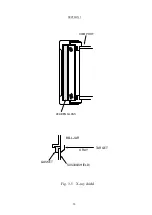

Page 13: ...SECTION 1 3 Fig 1 1 Dimensional Drawing for EGL 206M EGL 406M...

Page 24: ...SECTION 3 14 Fig 3 1 Installation of two or more electron beam guns...

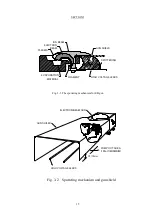

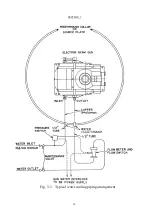

Page 26: ...SECTION 3 16 Fig 3 3 Typical water cooling piping arrangement...

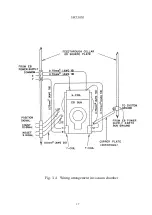

Page 27: ...SECTION 3 17 Fig 3 4 Wiring arrangement in vacuum chamber...

Page 38: ...SECTION 5 28 Fig 5 1 Exploded view of emitter assembly and dimensional drawing for electrode...

Page 42: ...SECTION 5 32 Fig 5 2 Exploded view of EGL 206M EGL 406M...