SECTION 5

29

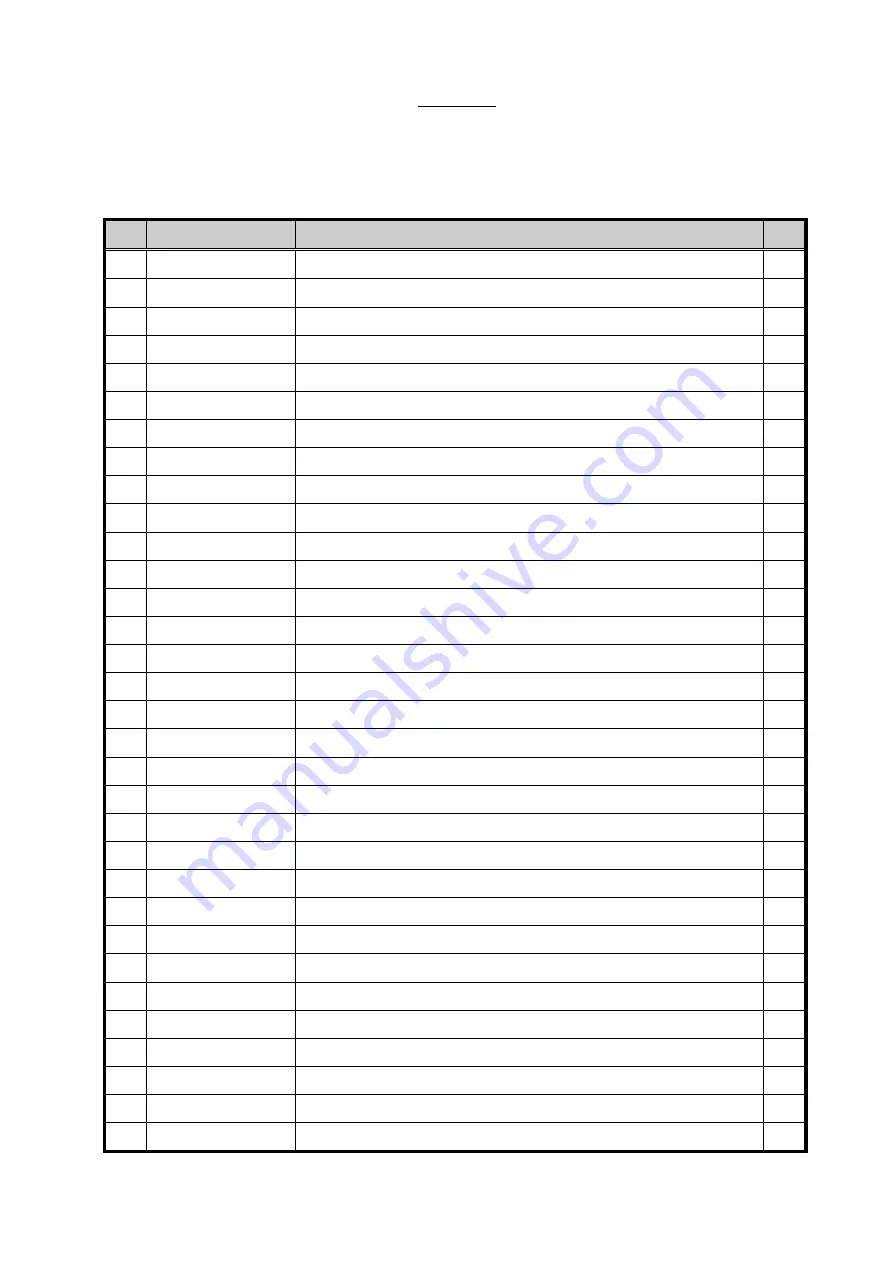

5.3 Parts List

EGL-206M/EGL-406M ( 1/3 )

No.

Part No.

Description

Q

’

ty

1

-

EGL-206M/EGL-406M One set of E/B gun

-

2

200001660700

Shield

SUS304

1

3

210004014000

Hearth deck

1

4

C10000000417

O-ring

Viton JIS B2401 P9

4

5

200001615100

Vacuum joint (1)

Cu

2

6

200001660900

Trimming piece

2

7

200001661000

Holder

SUS304

1

8

210004030200

Setscrew

SUS304

2

9

200001661200

Y-axis magnet pole (right)

1

10

200001661400

Y-axis magnet pole ( left )

1

11

200001661600

Y-axis iron core

2

12

210004016100

Y-axis magnet coil

2

13

200001661800

Main magnet pole ( right )

1

14

200001662000

Main magnet pole ( left )

1

15

200001662100

Hearth cover (2)

SUS304

1

16

200001662200

Hearth cover (1)

SUS304

2

17

200001662400

Adaptor ( right )

1

18

200001662600

Adaptor ( left )

1

19

210004015500

X-axis magnet coil

1

20

200007218400

Piping

Cu

1

21

200001662900

Thrust washer

1

22

200001663000

Centering ring WS2035

1

23

200001663100

Thrust needle bearing NTB2035

1

24

200001663200

Centering ring

GS2035

1

25

C10000000001

O-ring

Neoprene ISO No. 210

1

26

210004039700

Hearth

1

27

210004030300

Bevel gear (1)

SUS304

1

28

200001663400

Bearing

#6907

1

29

C10000000002

O-ring

Neoprene ISO No. 213

4

30

200001663500

Hearth shaft

SUS304

1

31

200001663600

Water outlet port SUS304

1

32

200001663700

Water inlet port

SUS304

1

Summary of Contents for EGL-206M

Page 2: ...EB0007 03e...

Page 3: ...EB0007 03e...

Page 10: ......

Page 13: ...SECTION 1 3 Fig 1 1 Dimensional Drawing for EGL 206M EGL 406M...

Page 24: ...SECTION 3 14 Fig 3 1 Installation of two or more electron beam guns...

Page 26: ...SECTION 3 16 Fig 3 3 Typical water cooling piping arrangement...

Page 27: ...SECTION 3 17 Fig 3 4 Wiring arrangement in vacuum chamber...

Page 38: ...SECTION 5 28 Fig 5 1 Exploded view of emitter assembly and dimensional drawing for electrode...

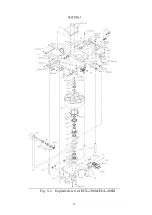

Page 42: ...SECTION 5 32 Fig 5 2 Exploded view of EGL 206M EGL 406M...