YK10-0015-DI-002-03

23

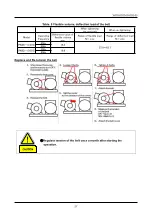

CAUTION

●

Read “1. 2 Chemical Material Safety Data Sheet” previously before

starting lubrication.

Please obtain the latest version of Material Safety Data Sheet (SDS)

from our Sales Department.

●

Weal protective gears such as rubber gloves, protective goggle and

so on.

Should the oil touched to your hand are entered in your eye,

immediately follow the emergency treatment described on the SDS.

CAUTION

●

Ensure to use the vacuum pump oil designated by ULVAC.

Operation using oil other than designated shall be out of our scope

of guarantee as it might impair the pump performance and shorten

the life cycle.

CAUTION

●

To lubricate, be sure to stop running the pump and return the

Mechanical booster inside to the atmospheric pressure.

Chamber containing the oil becomes vacuum during operation.

Taking off the plug during operation would cause a large leak and

give damage to the Pump unit.

CAUTION

●

Running the unit with the lubrication filled over the upper limit on

the room temperature (around 20

℃

) might cause the oil flowing in

the casing. Discharge the oil if over lubricated so as to match the

upper level.

●

Be sure to check the oil level under operation stop on the room

temperature (around 20

℃

.)

Oil level might get higher during operation due to the oil

temperature rise and oil rowing, but it makes no problem.

CAUTION

●

Note to purge the oil to transfer the pump. If forced to transfer

remaining the oil, be sure to keep the pump horizontal. Do not tilt

the pump 10 degree or more while you charge the oil. The oil might

run into the casing.

Summary of Contents for PMB-040C

Page 2: ......

Page 27: ...YK10 0015 DI 002 03 7 2 3 Dimensional drawing Fig 3 Dimensional drawing PMB 040C...

Page 28: ...YK10 0015 DI 002 03 8 Fig 4 Dimensional drawing PMB 060C...

Page 29: ...YK10 0015 DI 002 03 9 Fig 5 Foundation Drawing Model PMB 040C...

Page 30: ...YK10 0015 DI 002 03 10 Fig 6 Foundation Drawing Model PMB 060C...