YK10-0015-DI-002-03

25

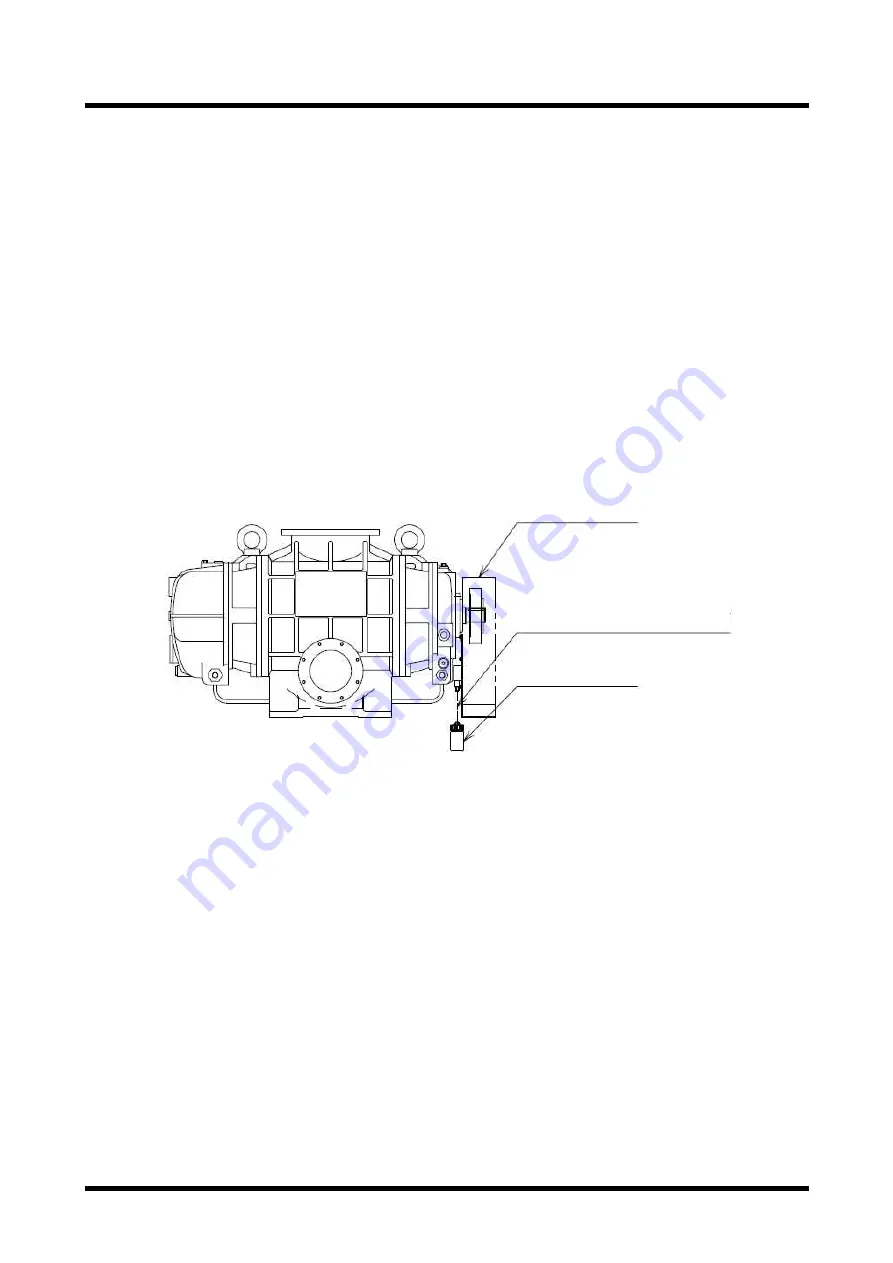

3.7 Oil Pot

The mechanical seals structurally cause a slight oil leakage under normal conditions. Approx. one

month after the startup is the running-in period of the sealing surfaces of the mechanical seals and

the amount of leakage may increase temporarily.

In addition, during the running-in period the mechanical seals may cause a metallic noise of high

frequency.

Receiving spilt oil in the oil pot prevents environmental pollution. Connect between the oil pot and

the pump body using the attached nylon tube and secure it using cable ties etc. so that the oil pot is

positioned below the body.

If the amount of oil leakage from the mechanical seals reaches 0.3 ml/hour or more after the use for

a certain period of time, the mechanical seals may deteriorate. In such a case, the mechanical seals

need to be replaced. Contact the nearest service center.

Fig. 10 Oil pot

Belt cover

Oil pot

Nylon tube

Summary of Contents for PMB-040C

Page 2: ......

Page 27: ...YK10 0015 DI 002 03 7 2 3 Dimensional drawing Fig 3 Dimensional drawing PMB 040C...

Page 28: ...YK10 0015 DI 002 03 8 Fig 4 Dimensional drawing PMB 060C...

Page 29: ...YK10 0015 DI 002 03 9 Fig 5 Foundation Drawing Model PMB 040C...

Page 30: ...YK10 0015 DI 002 03 10 Fig 6 Foundation Drawing Model PMB 060C...