YK10-0015-DI-002-03

30

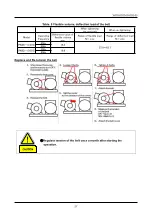

4.2.2 Exhaust start

(1) Flow the Cooling water.

(2) Close the main valve of the Mechanical booster pump and start running the backing pump to

exhaust inside pipes.

(3) Open the mechanical pump on the suction side of the mechanical booster pump, and exhaust

inside the vacuum vessel.

(4) Start the operation upon the vacuum chamber was exhausted to the pressure lower than the

maximum inlet pressure of the Mechanical booster pump.

4.3 Exhaust stop/Operation Stop

WARNING

●

Ensure to flow the cooling water with the specified volume. Lack of

the cooling water might give damage to the Pump unit or evaporate

the water remained in the Pump to raise the pressure inside the

Cooling system resulting in accidentally jetting out the hot steam.

●

The vacuum pump becomes high temperature during operation. Do

not touch the Motor and/or Pump unit until the Pump cools down

after having stopped operation. Apply an appropriate protection to

avoid to touch the surface as necessary.

●

However, if the environment was highly humid, keep the mechanical

booster pump warmer than the room temperature after having

stopped it and make the atmospheric pressure inside the pump.

Water in the air might condense in the pump and worsen the ultimate

pressure and/or pumping speed.

CAUTION

●

Be sure to close the vacuum valve and stop the Pump operation to

open the Leak valve. Failure to follow this operation might cause the

oil invasion in the casing from the lubrication chamber or otherwise

give damage to the Pump. Further the oil might flow back to the

Vacuum tank if used the oil rotation pump as the Supplementary

pump.

●

If failed in closing the Vacuum valve, the vacuum might leak from the

Exhaust system through the Pump.

CAUTION

●

If there are valves on the side of the air intake or exhaust ports of the

mechanical booster pump, you can close these valves to keep the

inside of the mechanical booster pump in a vacuum.

Summary of Contents for PMB-040C

Page 2: ......

Page 27: ...YK10 0015 DI 002 03 7 2 3 Dimensional drawing Fig 3 Dimensional drawing PMB 040C...

Page 28: ...YK10 0015 DI 002 03 8 Fig 4 Dimensional drawing PMB 060C...

Page 29: ...YK10 0015 DI 002 03 9 Fig 5 Foundation Drawing Model PMB 040C...

Page 30: ...YK10 0015 DI 002 03 10 Fig 6 Foundation Drawing Model PMB 060C...