SECTION 5

INSTALLATION

32

5

5.1.2.3 Installation of UTM1200 Series

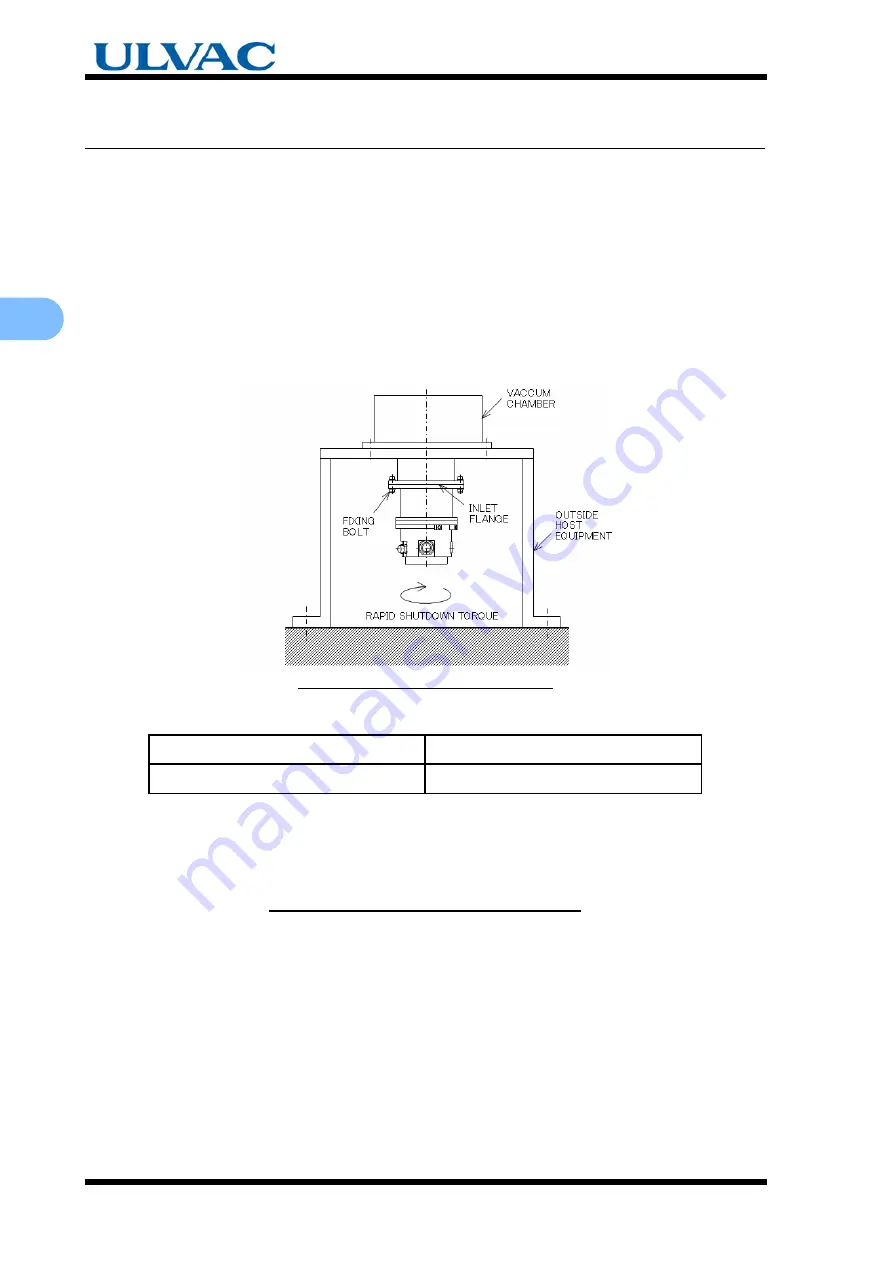

Please fix the inlet flange of the turbo molecular pump to the flange of vacuum chamber (Refer

to Fig. 5-6).

When you fix the pump, use of the bolts regulated grade, size, number and tightening torque

(Refer to Table 5-4 and Table 5-5). And use all the bolt-holes of the inlet flange of the pump. Refer

to Fig. 5-5 about usage of the bolt.

The sets of half-thread bolt and nut should be used to fix the inlet flange of the pump. Make

installation with the cylindrical part of the bolt (not thread part) fit in the mating section of flanges.

When you connect piping or valve between the chamber and the pump, please fix the same

method as the inlet flange.

Fixed only by the inlet flange of TMP

(Note 1) Rapid shutdown torque is the typical value measured by the ULVAC’s test condition. The

torque to transmit to host equipment might be different according to the rigidity of host

equipment. Host equipment should be designed to have enough margins in strength.

Fig. 5-6

Installation of UTM1200 Series

Description

Rapid shutdown torque (Note 1)

UTM1200 Series

27500 N•m

Summary of Contents for UTM1200 Series

Page 2: ...This page is intentionally left blank...

Page 10: ...viii Location of Label...

Page 26: ...12 2 2 4 External I F Panel This page is intentionally left blank...

Page 32: ...18 3 3 3 Controller This page is intentionally left blank...

Page 38: ...24 4 4 4 Standards Fulfilled This page is intentionally left blank...

Page 54: ...40 5 5 5 Notes on Transportation This page is intentionally left blank...

Page 78: ...64 6 6 8 Communication Specifications This page is intentionally left blank...

Page 79: ...7 7GAS PURGE...

Page 88: ...74 8 8 6 Turbo Molecular Pump Return Request This page is intentionally left blank...

Page 101: ...10 10WARRANTY CLAUSES...

Page 104: ...90 10 This page is intentionally left blank...

Page 106: ...Index Index 2 This page is intentionally left blank...