Table of Contents

Sections marked with a gray background ( ) are those which are concerned with the safe

use of this product.

Safety Precautions

(1) Introduction ------------------------ ------------------------------------------------ 1

1. Intended users ------------------------------------------------------------- 1

2. How to use this manual --------------------------------------------------- 1

3. Storing the user manual -------------------------------------------------- 1

4. Warranty ---------------------------------------------------------------------- 1

5. Obeying laws and regulations ------------------------------------------- 1

6. Safety management during repairs ------------------------------------ 1

(2) Product Overview ----------------------------------------------------------------- 2

1. Uses of this product and prohibitions ---------------------------------- 2

2. Purpose and function of safety equipment --------------------------- 2

3. Specifications---------------------------------------------------------------- 3

4. Individual equipment specifications ------------------------------------ 3

5. Standard accessories ----------------------------------------------------- 5

6. How to use the switches, handle and operation lever ------------- 6

7. Layout of the switches, handle and operation lever---------------- 7

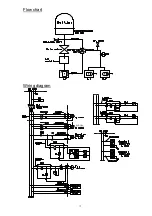

Flow chart--------------------------------------------------------------------- 8

Wiring diagram -------------------------------------------------------------- 8

(3) Unpacking and installation--------------------------------------------------- 9

1. General precautions ------------------------------------------------------- 9

2. Delivery packaging --------------------------------------------------------- 9

3. Installation -------------------------------------------------------------------- 9

4. Power supply ---------------------------------------------------------------- 10

5. Water -------------------------------------------------------------------------- 11

6. List of necessary tools----------------------------------------------------- 11

7. Attaching the hoist---------------------------------------------------------- 12

8. Attaching the liquid nitrogen intake ------------------------------------ 13

9. Checking the direction of the oil-sealed rotary vacuum pump--- 14

(4) Operating ------------------------------------------------------------------------ 15

1. Dangers and safety guidelines during operation-------------------- 15

2. Inspecting the device before use --------------------------------------- 16

3. Using the exhaust port ---------------------------------------------------- 16

3-1 Preparation ----------------------------------------------------------- 16

3-2 Operation ------------------------------------------------------------ 16

3-3 Shutting down ------------------------------------------------------- 17