SK00-4390-DI-002-11

35

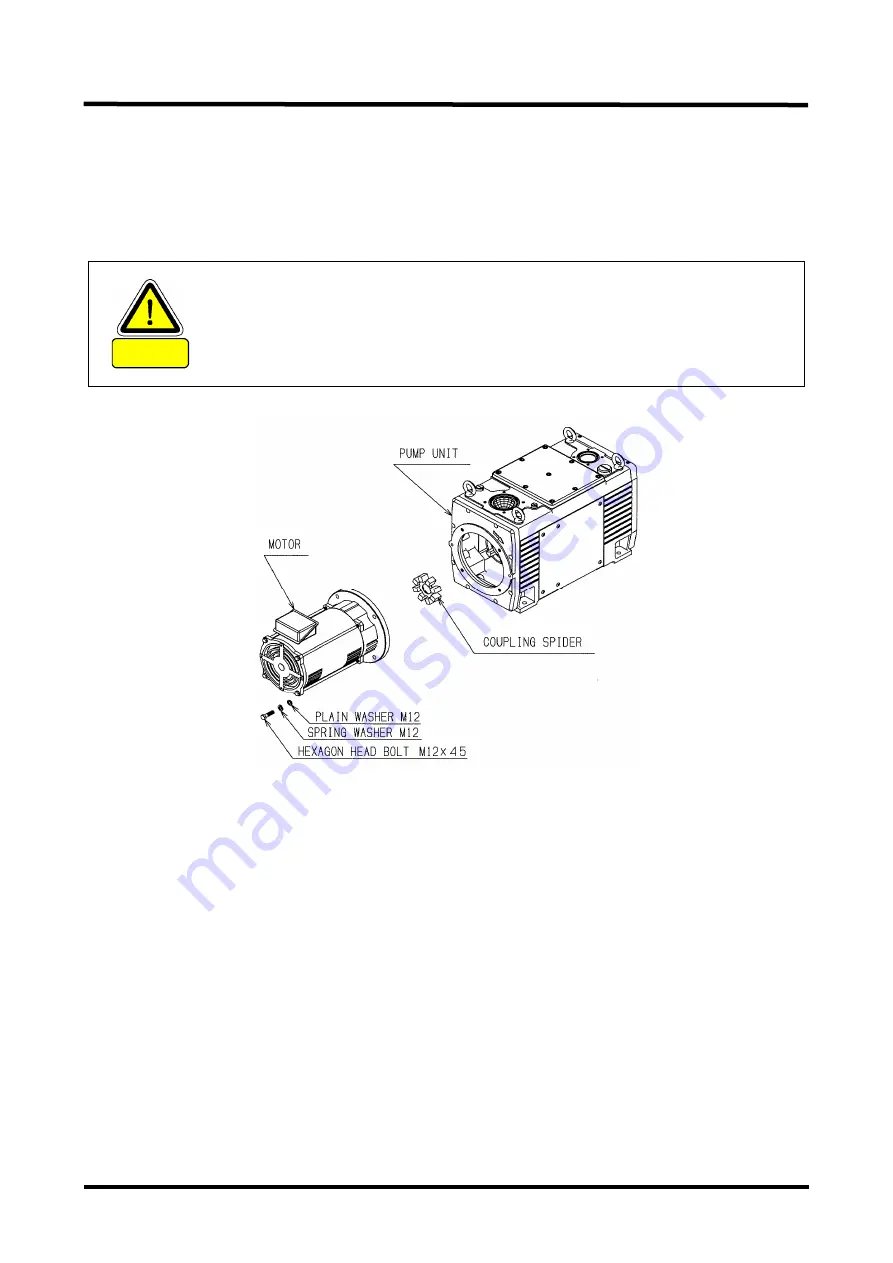

(5) Put the new coupling spider in one of the coupling. Meet the ratchet of both couplings and

mount the pump unit in the medium case.

(6) Put the M12 hexagon head bolt x 4 and spring washer x 4 and plain washer x 4 removed

in the item (2) above (Recommended tightening torque: 45N

・

m).

(7) Execute the wiring.

CAUTION

Use the loading equipment such as a crane to put on and take out the

Motor to ensure the safety. Be sure to turn OFF the Power Supply when

putting on and taking out the Motor.

Only the technically entitled person should be in charge of operating the

machine such as crane.

Fig. 10 Replacement of coupling spider

6.2.9 Checking The Oil Mist Trap

To use the Oil mist trap, be cautious not to have clog of the filter in the trap. Too much clog

would prevent the exhaust gas from passing through the filter, raise the pressure inside the

Pump unit and might result in breaking it.

Limit value of the pressure inside the Pump is 0.03MPaG (0.3kg/cm

2

G) (Gauge pressure). We

recommend you to install a Pressure monitor. Refer to the Instruction Manual of the Oil mist

trap as for the install position of the Pressure monitor.

It is recommended to mount a pressure monitor (G1/4). For the pressure monitor mounting

position, refer to the instruction manual for the oil mist trap.

Summary of Contents for VS1501

Page 2: ......

Page 13: ...SK00 4390 DI 002 11 xi Fig 1 Warning Label display position...

Page 27: ...SK00 4390 DI 002 11 7 Fig 2 VS1501 Dimensional drawing...

Page 28: ...SK00 4390 DI 002 11 8 Fig 3 VS2401 Dimensional drawing...

Page 36: ...SK00 4390 DI 002 11 16 Fig 5 Suction Exhaust piping connection diagram...