Appendix

78/92

11 Appendix

11.1

Parameter list

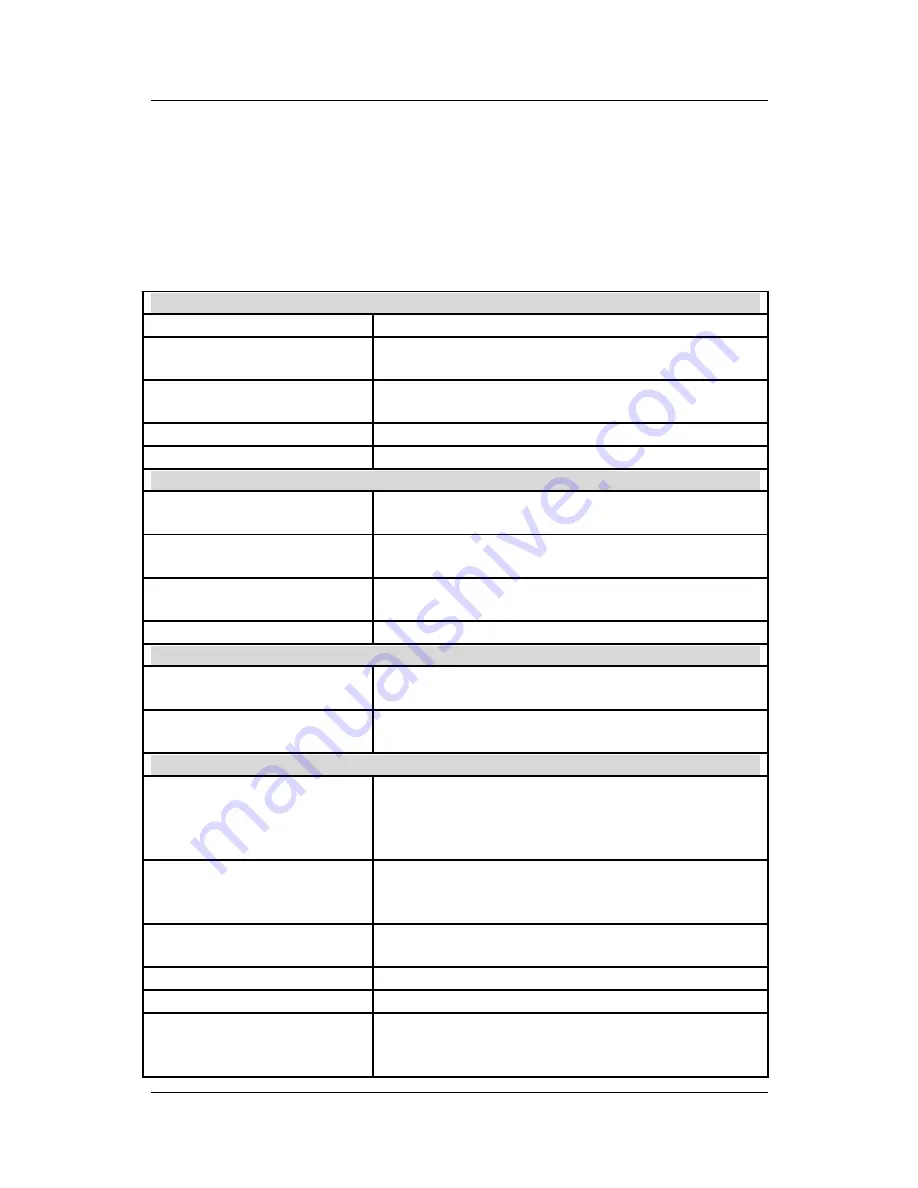

11.1.1 Input

Geometric variables:

V [cm] FLOAT

Soil sample volume

z

1

[cm] FLOAT

Height of Tensiometer 1 (over bottom of soil

sample)

z

2

[cm] FLOAT

Height of Tensiometer 2 (over bottom of soil

sample)

L [cm] FLOAT

Length of the soil sample

For generating data points:

INTERPOL INTEGER

Type of data interpolation: 0: polynomial; 1:

partially linear; 2: hermitical spline)

nbt INTEGER

Max. number of data points for the hydraulic

function

OPTIMI LOGICAL

If TRUE, then optimization is executed, if

FALSE only data points are generated

NDEG INTEGER

If INTERPOL = 0, then order of the polynomial

Measuring inaccuracy:

σ

h

[cm] FLOAT

Measuring error of the potential (standard

deviation)

σ

w

[g] FLOAT

Measuring error of the weight (standard

deviation)

For parameter estimation:

CODE INTEGER

Type of model

10: van Genuchten/Mualem

11: van Genuchten/Mualem bimodal

20: Brooks/Corey)

INIT FLOAT (vector)

Start up estimation of parameters, respectively

the fix value if parameter x should not be

estimated

OPTP LOGICAL (vector)

Indicator if parameter x should be optimized or

not

IN_MAXOPTIT INTEGER

Obsolete! Must always be 1!

W_DEV FLOAT

Obsolete! Not condsidered

IN_WEIGHTFLAG

LOGICAL

If TRUE then both hydraulic functions are

automatically rated as described in chapter „Fit

of parametric expressions to the

θ

(h) and K(h)